angle offset in cnc machine There are a variety of ways to increase the flexibility and capability of a three-axis machine tool. One is to use angle heads, which can enable horizontal and angular milling and . $9.99

0 · work offset for cnc

1 · how to set offset cnc

2 · cnc offsets chart

3 · cnc offset types

4 · cnc offset tool

5 · cnc head offset

6 · cnc angle offset

7 · cnc angle head offset

Cover for Underground Enclosure, R Series, 10 x 15 x 1-3/4 Inch, Legend: ELECTRIC, Skid Resistant, Rated Light Duty/Pedestrian Traffic, Composite With UV Inhibitor

metal fabricators daytona beach daytona beach fl

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for. How about one of those ball end electronic edge finders? Set it up permanently in a tool holder as a reference tool and record the length offset. Angle your head and touch off .

There are a variety of ways to increase the flexibility and capability of a three-axis machine tool. One is to use angle heads, which can enable horizontal and angular milling and . Here is a macro I developed to allow operators to calculate their own fixture offsets right on the machine. The macro tracks any point on the work piece as it indexes on the rotary . You can check CNC Offset Calculator - it's a program that does the calculation of offsets on HMC. It calculates the values of X,Y,Z coordiantes or makes a program for CNC . We have 8 identical features to cut using a right angled head on our Machine, Each feature requires 8 different tools. At the current moment we are setting each "X" Offset .

metal fabricators gulfport gulfport ms

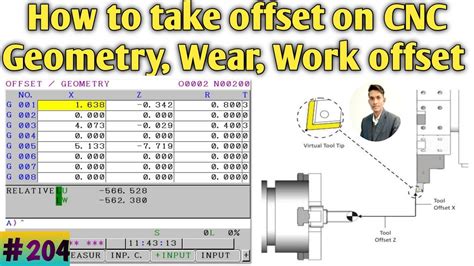

Picking up a WCS on a compound angle can also be done if you're using a sophisticated post processor like CAMplete; you can measure the difference between the real . There are two types of offsets required for work. Tool offset is nothing but the required values and measures we use to style a tool and shift the position of the tool. If we all know the precise tool offsets, we will find the .In the latest Tip of the Day, Mark shows how to use your Haas probing system to quickly pick up a work offset and find the angle of your workpiece. If you've ever struggled to indicate your part .Mastering offset turning on a CNC lathe is a valuable skill that can greatly enhance your machining capabilities. By understanding how to properly set up and utilize offsets, you can .

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for. How about one of those ball end electronic edge finders? Set it up permanently in a tool holder as a reference tool and record the length offset. Angle your head and touch off X,Y,Z. Then you can use it to pick up a location on the part and get the length of your drills and taps.

There are a variety of ways to increase the flexibility and capability of a three-axis machine tool. One is to use angle heads, which can enable horizontal and angular milling and drilling without requiring the workpiece to be repositioned for a secondary operation. Here is a macro I developed to allow operators to calculate their own fixture offsets right on the machine. The macro tracks any point on the work piece as it indexes on the rotary axis. You can check CNC Offset Calculator - it's a program that does the calculation of offsets on HMC. It calculates the values of X,Y,Z coordiantes or makes a program for CNC control using system variables and the CNC control calculates offset values dynamically when it runs. We have 8 identical features to cut using a right angled head on our Machine, Each feature requires 8 different tools. At the current moment we are setting each "X" Offset individually for each tool and programming point to point. This is obviously fairly time consuming and also adds an element of risk of incorrectly setting each time.

Picking up a WCS on a compound angle can also be done if you're using a sophisticated post processor like CAMplete; you can measure the difference between the real setup probe location versus where it would be with the table flat, and then transform the point in the software prior to posting. There are two types of offsets required for work. Tool offset is nothing but the required values and measures we use to style a tool and shift the position of the tool. If we all know the precise tool offsets, we will find the precise machining start line.

In the latest Tip of the Day, Mark shows how to use your Haas probing system to quickly pick up a work offset and find the angle of your workpiece. If you've ever struggled to indicate your part in the old-fashioned way – and who hasn't? – then this tip is for you!

Mastering offset turning on a CNC lathe is a valuable skill that can greatly enhance your machining capabilities. By understanding how to properly set up and utilize offsets, you can achieve precise results and maximize the efficiency of your turning operations. Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for. How about one of those ball end electronic edge finders? Set it up permanently in a tool holder as a reference tool and record the length offset. Angle your head and touch off X,Y,Z. Then you can use it to pick up a location on the part and get the length of your drills and taps. There are a variety of ways to increase the flexibility and capability of a three-axis machine tool. One is to use angle heads, which can enable horizontal and angular milling and drilling without requiring the workpiece to be repositioned for a secondary operation.

Here is a macro I developed to allow operators to calculate their own fixture offsets right on the machine. The macro tracks any point on the work piece as it indexes on the rotary axis. You can check CNC Offset Calculator - it's a program that does the calculation of offsets on HMC. It calculates the values of X,Y,Z coordiantes or makes a program for CNC control using system variables and the CNC control calculates offset values dynamically when it runs. We have 8 identical features to cut using a right angled head on our Machine, Each feature requires 8 different tools. At the current moment we are setting each "X" Offset individually for each tool and programming point to point. This is obviously fairly time consuming and also adds an element of risk of incorrectly setting each time.

Picking up a WCS on a compound angle can also be done if you're using a sophisticated post processor like CAMplete; you can measure the difference between the real setup probe location versus where it would be with the table flat, and then transform the point in the software prior to posting. There are two types of offsets required for work. Tool offset is nothing but the required values and measures we use to style a tool and shift the position of the tool. If we all know the precise tool offsets, we will find the precise machining start line.

In the latest Tip of the Day, Mark shows how to use your Haas probing system to quickly pick up a work offset and find the angle of your workpiece. If you've ever struggled to indicate your part in the old-fashioned way – and who hasn't? – then this tip is for you!

work offset for cnc

how to set offset cnc

cnc offsets chart

$29.49

angle offset in cnc machine|work offset for cnc