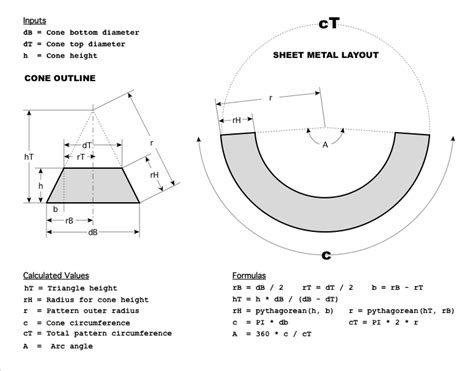

development of a cone sheet metal enter finished cone dimensions: d = diameter of large end: d1 = diameter of small end: h = height of cone: n = number of plates: lr = large layout rad * sr = small layout rad * ang = angle of segment:

Custom Metal Fabrication. Our state-of-the-art shop features high-speed lasers, .

0 · sheet metal cone layout

1 · sheet metal cone formula

2 · sheet metal cone chart

3 · sheet metal cone calculator

4 · how to calculate cone development

5 · how to calculate cone design

6 · cone layout design

7 · cone design examples

$58.99

So, in this post, we are covering all the Points related to Full Cone Layout Development so that you can learn in-depth and used this method in daily fabrication activity. Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It .

Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.Project the element lines from the base to the apex of the cone. Locate a radius point where you want to develop the pattern. With your compass, take the large slant height from the elevation view and swing an arc from the radius point.

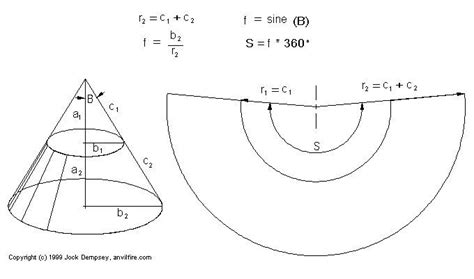

This generates the development for the cone, which is a sector of a circle with radius R and sector angle θ. To calculate the dimensions of the development, first the slant height of the cone must be found from Pythagoras' theorem, ie R = √ .enter finished cone dimensions: d = diameter of large end: d1 = diameter of small end: h = height of cone: n = number of plates: lr = large layout rad * sr = small layout rad * ang = angle of segment: What's important to remember with radial line development is all tapers (slants) must remain constant. (Left). First step, draw an elevation view of the cone (this can be any measurements) for this tutorial we used 12" as a .A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. Sheet metal layout drawings are based on three .

FastSHAPES® is the generic name for a suite of Plate & Sheet development software programs specifically designed for heavy fabrication where the main jointing technology is welding. The CONE software module is for the .

Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with Knuckle Radius at .

So, in this post, we are covering all the Points related to Full Cone Layout Development so that you can learn in-depth and used this method in daily fabrication activity.Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number . Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.Project the element lines from the base to the apex of the cone. Locate a radius point where you want to develop the pattern. With your compass, take the large slant height from the elevation view and swing an arc from the radius point.

This generates the development for the cone, which is a sector of a circle with radius R and sector angle θ. To calculate the dimensions of the development, first the slant height of the cone must be found from Pythagoras' theorem, ie R = √ [ H^2 + ( D/2 )^2] .enter finished cone dimensions: d = diameter of large end: d1 = diameter of small end: h = height of cone: n = number of plates: lr = large layout rad * sr = small layout rad * ang = angle of segment: What's important to remember with radial line development is all tapers (slants) must remain constant. (Left). First step, draw an elevation view of the cone (this can be any measurements) for this tutorial we used 12" as a base and 5" as a top dia.A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. Sheet metal layout drawings are based on three types of .

FastSHAPES® is the generic name for a suite of Plate & Sheet development software programs specifically designed for heavy fabrication where the main jointing technology is welding. The CONE software module is for the development covers all .Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with Knuckle Radius at .So, in this post, we are covering all the Points related to Full Cone Layout Development so that you can learn in-depth and used this method in daily fabrication activity.

Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number . Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.Project the element lines from the base to the apex of the cone. Locate a radius point where you want to develop the pattern. With your compass, take the large slant height from the elevation view and swing an arc from the radius point.

This generates the development for the cone, which is a sector of a circle with radius R and sector angle θ. To calculate the dimensions of the development, first the slant height of the cone must be found from Pythagoras' theorem, ie R = √ [ H^2 + ( D/2 )^2] .enter finished cone dimensions: d = diameter of large end: d1 = diameter of small end: h = height of cone: n = number of plates: lr = large layout rad * sr = small layout rad * ang = angle of segment:

sheet metal cone layout

sheet metal cone formula

What's important to remember with radial line development is all tapers (slants) must remain constant. (Left). First step, draw an elevation view of the cone (this can be any measurements) for this tutorial we used 12" as a base and 5" as a top dia.

A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. Sheet metal layout drawings are based on three types of .

sheet metal cone chart

sheet metal cone calculator

how to calculate cone development

This magical box of coolness in the corner of the kitchen was the epicenter of cold storage from the mid-19th to early 20th century, transforming food preservation and the way households operated. Antique iceboxes, aptly named for the large blocks of ice they held, were usually made of wood, lined with tin or zinc, and insulated with sawdust .

development of a cone sheet metal|sheet metal cone chart