cnc machine inserts for turning Wiper inserts are capable of turning at high feed rates without losing the capability to generate good surface finish or chip breaking ability. Uniform component shapes. Note: Wiper insert is . Deck Support Column Checklist. Wood is good but steel is supreme; 6x6 wood posts are best; 4x4 steel columns last forever; Local welders can make steel columns fast

0 · types of machining inserts

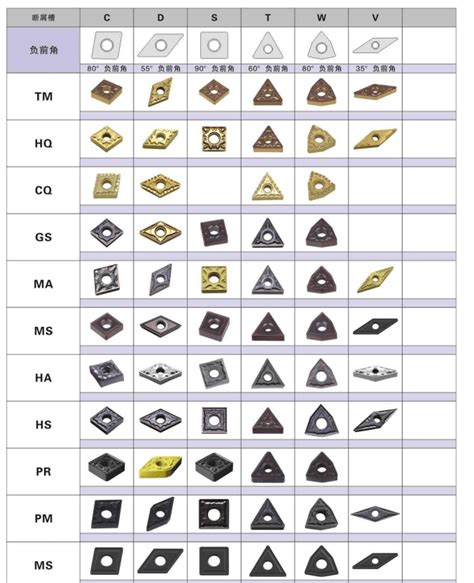

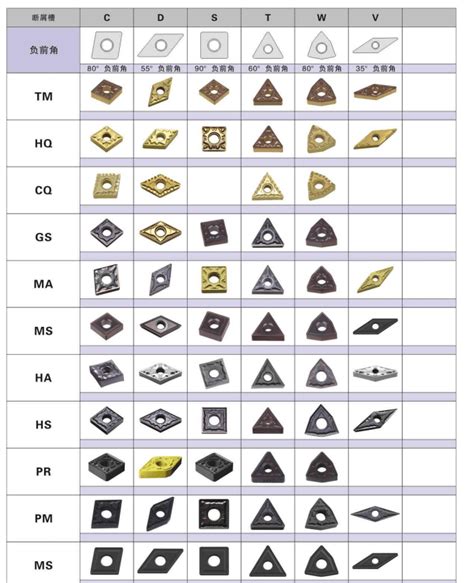

1 · turning inserts chart

2 · sacher cnc cutting insert

3 · how to choose a turning insert

4 · groove turning inserts

5 · geometry of turning insert

6 · different types of turning inserts

7 · best lathe insert for turning

$11.99

Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and .

There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining .There are many variables that go into choosing the correct insert for your turning operations: insert shape, geometry, grade, and more. The goal is to select an insert that meets your requirements for quality and performance, while .

The most common are turning inserts, groove-turning inserts, inserts for cutting hard materials, and thread-turning inserts. In addition, cutting inserts are available in many colors, which helps identify them.

Wiper inserts are capable of turning at high feed rates without losing the capability to generate good surface finish or chip breaking ability. Uniform component shapes. Note: Wiper insert is .Whatever your component or requirements for surface finish, find productive insert grades here that can withstand high temperatures and cutting forces and still retain their cutting edges. This CBN grade is your first choice for case and . Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Understanding the material properties and machining conditions is crucial for .

There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance.There are many variables that go into choosing the correct insert for your turning operations: insert shape, geometry, grade, and more. The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness.The most common are turning inserts, groove-turning inserts, inserts for cutting hard materials, and thread-turning inserts. In addition, cutting inserts are available in many colors, which helps identify them.

Wiper inserts are capable of turning at high feed rates without losing the capability to generate good surface finish or chip breaking ability. Uniform component shapes. Note: Wiper insert is not recommended for internal machining with long overhang due to vibration.Whatever your component or requirements for surface finish, find productive insert grades here that can withstand high temperatures and cutting forces and still retain their cutting edges. This CBN grade is your first choice for case and induction hardened steels. There are various CNC insert types available, each designed for specific machining operations and materials. Some common types include: Turning inserts: Used for cylindrical turning operations. Milling inserts: Designed for face milling, shoulder milling, and other milling applications. In this post, we will focus on the “go-to” workhorse insert shapes that are the most popular for job shop CNC turning operations: 80° Diamond, or “C-Style” inserts 80° Trigon, or “W-Style” inserts

This article will detail the types, materials, machining methods, coatings, advantages, hardness, and lifespan of inserts. Types of Inserts Turning Inserts: Mainly used for turning operations, suitable for external, internal, and face turning. Milling Inserts: Used for milling operations, including face milling, end milling, and slot milling.In this comprehensive guide, we will dive deep into the world of CNC turning inserts, explore the different types, materials, and coatings available, and provide essential tips on how to choose the right insert for optimal efficiency.

types of machining inserts

Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Understanding the material properties and machining conditions is crucial for .There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance.There are many variables that go into choosing the correct insert for your turning operations: insert shape, geometry, grade, and more. The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness.The most common are turning inserts, groove-turning inserts, inserts for cutting hard materials, and thread-turning inserts. In addition, cutting inserts are available in many colors, which helps identify them.

flush fitted electricity meter box cover

Wiper inserts are capable of turning at high feed rates without losing the capability to generate good surface finish or chip breaking ability. Uniform component shapes. Note: Wiper insert is not recommended for internal machining with long overhang due to vibration.Whatever your component or requirements for surface finish, find productive insert grades here that can withstand high temperatures and cutting forces and still retain their cutting edges. This CBN grade is your first choice for case and induction hardened steels.

There are various CNC insert types available, each designed for specific machining operations and materials. Some common types include: Turning inserts: Used for cylindrical turning operations. Milling inserts: Designed for face milling, shoulder milling, and other milling applications.

floor mount electrical enclosure

turning inserts chart

In this post, we will focus on the “go-to” workhorse insert shapes that are the most popular for job shop CNC turning operations: 80° Diamond, or “C-Style” inserts 80° Trigon, or “W-Style” inserts This article will detail the types, materials, machining methods, coatings, advantages, hardness, and lifespan of inserts. Types of Inserts Turning Inserts: Mainly used for turning operations, suitable for external, internal, and face turning. Milling Inserts: Used for milling operations, including face milling, end milling, and slot milling.

sacher cnc cutting insert

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing valuable insights for DIY enthusiasts.

cnc machine inserts for turning|best lathe insert for turning