axis on cnc machine Learn about the different types of CNC milling machines, how they work, and why they are precise. Find out the advantages and disadvantages of linear motor, closed-loop control, and multi-axis linkage. $199.99

0 · what is 5 axis machining

1 · cnc mill axis diagram

2 · cnc machine axis identification

3 · cnc axis explained

4 · 4 axis cnc milling machine

5 · 4 axis cnc mill

6 · 3 axis cnc milling machine

7 · 12 axis cnc machine

Blue and gold metallic flourishes on a spice red background, 100% cotton, 44" wide

Learn what a 6 axis CNC machine is, how it works, and how it compares to other CNC machines. Find out the advantages, applications, and challenges of using a 6 axis CNC . There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool . Learn about the different types of CNC milling machines, how they work, and why they are precise. Find out the advantages and disadvantages of linear motor, closed-loop control, and multi-axis linkage. In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

6 axis CNC: A 6 axis CNC machine is a type of CNC machine that can move and rotate its cutting tool or workpiece in six different directions. It can perform complex and precise operations that are impossible or difficult with conventional CNC machines. There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece.

tube for steel guitar black box

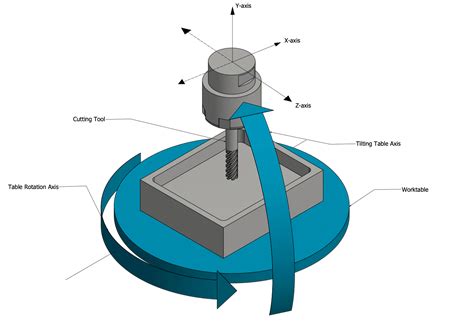

Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. The figure above shows the main control parts of a CNC mill, including the human-machine interface (computer), controller, amplifier, encoder, motor, ball screw, and guide rail.

CNC lathe machines vary in the number of axes they use, which significantly affects their capabilities and the complexity of parts they can produce. Let’s break down the different types of CNC lathes based on the number of axes they include. 2-axis CNC lathes are the most basic type. These machines operate along the X and Z axes. All machines start with three axes. The three axes model performs essential functions and, in the hands of an experienced machinist, can be used for more advanced creations. Four axes on a CNC machine add an extra cutting direction, which increases precision. Most CNC machines are either 3- or 5-axis, and, in this article, we’ll look at their differences and what they’re each good for. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes.

CNC (Computer Numerical Control) machines utilize multiple axes to perform precise cutting and shaping operations. The number of axes directly influences the machine’s ability to manipulate the workpiece, the complexity of parts it .

Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, it can . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better. In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers. 6 axis CNC: A 6 axis CNC machine is a type of CNC machine that can move and rotate its cutting tool or workpiece in six different directions. It can perform complex and precise operations that are impossible or difficult with conventional CNC machines.

There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece. Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. The figure above shows the main control parts of a CNC mill, including the human-machine interface (computer), controller, amplifier, encoder, motor, ball screw, and guide rail.

CNC lathe machines vary in the number of axes they use, which significantly affects their capabilities and the complexity of parts they can produce. Let’s break down the different types of CNC lathes based on the number of axes they include. 2-axis CNC lathes are the most basic type. These machines operate along the X and Z axes. All machines start with three axes. The three axes model performs essential functions and, in the hands of an experienced machinist, can be used for more advanced creations. Four axes on a CNC machine add an extra cutting direction, which increases precision. Most CNC machines are either 3- or 5-axis, and, in this article, we’ll look at their differences and what they’re each good for. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. CNC (Computer Numerical Control) machines utilize multiple axes to perform precise cutting and shaping operations. The number of axes directly influences the machine’s ability to manipulate the workpiece, the complexity of parts it .

tungsten sheet metal price

tuffbilt metal wall bracket

what is 5 axis machining

$52.00

axis on cnc machine|3 axis cnc milling machine