sheet metal classification Hand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The . See more Most exterior sheet metal from the 30's to about the 80's was Aluminum killed draw quality 19ga steel which was softer then mild steel, not some mythical magic metal. If you do one continuous weld your need to "hammer weld" will decrease. If you look at the HAZ, the spot you start and stop, the HAZ appears to look like a Figure 8.

0 · what is sheet metal

1 · what are sheet metal parts

2 · types of sheet metal parts

3 · types of sheet metal

4 · sheet steel grades

5 · list of sheet metals

6 · grades of sheet metal

7 · examples of sheet metal

Below we have common materials and what type of glue or adhesive to use to hold them together. Glue Guide For All Types Of Materials – What Type Of Glue To Use On. Glass To Metal – Loctite Impruv; Metal To Wood – LePage’s Metal Epoxy; Plastic To Metal – Faststeel Epoxy Putty; Leather To Metal – Household Goop; Felt To Metal – 3M 77

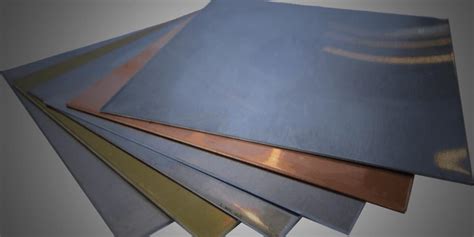

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or . See moreHand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The . See moreBendingThe equation for estimating the maximum bending force is,$${\displaystyle F_{\text{max}}=k{\frac {TLt^{2}}{W}}}$$,where k is a factor taking into account several parameters . See more

franklin electric control box parts

Fasteners that are commonly used on sheet metal include: clecos, rivets, and sheet metal screws. See more• "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See moreStainless steelGrade 304 is the most common of the three grades. It offers good corrosion resistance while . See moreThe use of sheet metal, through a comprehensive cold working process, including bending, shearing, punching, laser cutting, water jet cutting, riveting, splicing, etc. to make the final product we want (such as computer chassis, washing machine shells, . See more

• Circle grid analysis• Corrugated galvanised iron, also known as Corrugated Sheet Metal• Diamond plate• Forming limit diagram See more

Steel is typically categorized into types based on various criteria such as chemical composition, physical properties, and usage. Here are the four most common types of steel: Carbon steels. Alloy steels. Stainless steels. . Sheet metal is metal that has been formed into thin, flat pieces, usually through an industrial process. It is generally produced in sheets less . Codes for steel, aluminum, copper and other metal numbers used for grading, classification and designation purposes. Free brochures for download.

Steel can be classified into four main categories based on their shape: profiles, plates, pipes, and metal products. Wire rod: General wire, high carbon wire, threaded steel. Section steel:Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than . Explore the various classifications of metal sheet materials, their properties, and industrial applications in this comprehensive guide for engineers and fabricators. In this article, you will learn about 9 different types of Sheet Metal Operations with diagrams and you can also download the pdf file of this post.

The Sheet metal material selection during product design impact the sheet metal part design, manufacturing process, cost, and part performance. In this article, we will discuss sheet metal .

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. .Division 3, Chapter 9. Contractors, Article 4. Classifications. 7055. For the purpose of classification, the contracting business includes any or all of the following branches: . C-43 - Sheet Metal Contractor; C-45 - Sign Contractor; C-46 - Solar Contractor; C-47 - General Manufactured Housing Contractor; Craft/Classification: Sheet Metal Worker; Indentured/Other: Indentured prior to 1/1/16; Counties: Kern, Los Angeles (Portions North Of A Straight Line Drawn Through Gorman And Big Pines) Period Duration Months OJT Hours Basic Hourly Rate Health & Welfare Pension Vacation/ Holiday Training Other Total Hourly Rate; 1: 6: N/A: .600: .220: .100:

A “wage determination” is the listing of wage rates and fringe benefit rates for each classification of laborers and mechanics which the WHD Administrator has determined to be prevailing in a given area (usually a county) for a particular type of construction. . SHEE = Sheet Metal Workers International Association.

2. Cuts out sheet metal parts using hand or power tools, bends and forms pieces and fastens parts together with joining equipment. 3. Erects scaffolds for work to be done in high locations. 4. Lifts and sets sheet metal parts and objects in place and connects with other units. 5. Uses solder to join sheet metal parts and products. 6. 30. Drawing Sheet metal forming to make cup‑shaped, box‑shaped, or other complex‑curved, hollow‑shaped parts Sheet metal blank is positioned over die cavity and then punch pushes metal into opening Products: beverage cans, ammunition shells, automobile body panels Also known as deep drawing (to distinguish it from wire and bar drawing) ©2007 John .

After the first industrial applications [1, 2], simulation of sheet metal forming has become a feature of industrial part design.Most simulations carried out in industry use the so called “incremental” technique, where a Finite Element model of the stamping tools is created to follow step by step the contact between tools and metal blank.Study with Quizlet and memorize flashcards containing terms like Continuous filler metal electrodes can come in many forms such as coil, spool and what else?, Wire diameters of .020 and .030 are commonly used for sheet metal., Using the American Welding Society GMAW electrode Classification E71T-X, what does the T represent? and more. Phraseology: SHEET METAL PRODUCTS MFG. — shop only — N.O.C. Footnote: This classification applies to the manufacture of sheet metal products, including but not limited to brackets, chassis, panels and covers when more than 50% of the metal used is #15 gauge or lighter and metal stamping payroll, if any, does not exceed 10% of the total manufacturing payroll. Sheet-metal blanking is a class of metal fabricating processes that separate a metal workpiece from a primary metal sheet through a shearing process. Industry experts observe fluctuations in tool life and product quality, which is associated with fluctuations in microstructural parameters between and along material coils. With a methodology, that provides reliable .

Classification according to process properties A die that separates material along a closed or open contour. Such as blanking die,Classification according to process properties A die that separates material along a closed or open contour. Such as blanking die, punching die, cutting die, cutting die, trimming die, cutting die, etc. The bending die is a die that makes the .Study with Quizlet and memorize flashcards containing terms like The classification for high tensile strength fiberglass used in aircraft structures is, A category of plastic material that is capable of softening or flowing when reheated is described as a, The flat layout or blank length of a piece of metal from which a simple L-shaped bracket 3 inches by 1 inch is to be bent . Technology-Based Sheet Metal Classification and Coding System Group technology (GT) concept uses design similarity measure to identify the most similar design and retrieve a useful process plan. Manufacturing feature classification for sheet-metal features has been presented by Kannan and Shunmugam ().The manufacturing features in sheet-metal parts are classified into four major classes: cut, stretched, drawn, and bent as presented in Fig. 4.The major difference between stretched and drawn features is that a change in sheet thickness occurs in the .

fountain junction box

Sheet metal is a thin piece of metal between 0.006 and 0.25 inches thick. Sheet metal can be cut, bent, and stretched into various shapes through forming and cutting operations. Common forming operations include .Sheet Metal Mechanic, 3806 March 2007 SHEET METAL MECHANIC, 3806 (continued) Supervisors and Leaders Titling (continued) • Add the suffix “Supervisor” to the basic title when the agency determines the job is supervisory. If the job is covered by the Federal Wage System refer to the Federal Wage System Job Grading Standard for Supervisors for additional titling .The related NAICS Code(s) for NCCI Workers Compensation Class Code 5535 - Sheet Metal Work - Installation & Drivers is: 238390 - Other Building Finishing Contractors. This industry comprises establishments primarily engaged in building finishing trade work (except drywall, plaster, and insulation work; painting and wall covering work; flooring work; tile and terrazzo .Technology-Based Sheet Metal Classification and Coding System. Peter Šugár. Journal for Technology of Plasticity, 2011 .

The Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) is an international trade association representing 3,500 signatory contracting firms with more than 100 chapters throughout the United States, Canada, Australia, and Brazil. A leader in promoting quality and excellence in the sheet metal and air conditioning industry, SMACNA has offices in .5538 SHEET METAL WORK – Shop and outside – & Drivers NOC 3066 SHEET METAL WORK – SHOP. NY Class Code. 5538 Sheet Metal Work 3066 SHEET METAL WORK-SHOP ONLY. PA Class Code. 0664 Heating Or Ventilating 0454 Sheet Metal Products Fabrication. TX Class Code. 5538 Sheet Metal Work. Market Report. No Report Available. Accounts.

A Sheet Metal Stamping Classification System for Product/Process Design and Material Specification 920430. The paper describes a system currently under development, intended to be the spine for organizing an open-ended knowledge-based system for stampings within the sheet metal industry. The system is designed for those not necessarily expert . 2. Cuts out sheet metal parts using hand or power tools, bends and forms pieces and fastens parts together with joining equipment. 3. Erects scaffolds for work to be done in high locations. 4. Lifts and sets sheet metal parts and objects in place and connects with other units. 5. Uses solder to join sheet metal parts and products. 6.Explain the significance of the AWS filler metal classification RG45. RG is specific for fuel gas welding. 45 is tensile strength; 45000-55000 psi. . Which SMAW electrodes are commonly used to weld on sheet metal fabrications? 6013, 7014. Which SMAW electrodes can be used to weld on metal that has a light covering of paint? 6010, 6011, 7014. As the application of sheet metal continues to expand, the design of sheet metal parts has become a critical aspect of product development. Mechanical engineers must be well-versed in the design of sheet metal components to ensure that the parts meet the necessary functional and aesthetic requirements while keeping the stamping die production .

the basic hourly rate and employer payments are not taken from a collective bargaining agreement for this craft or classification. a . includes an amount for the sheet metal occupational health institute trust. ab includes amount for 401(a) plan. pursuant to labor code sections 1773.1 and 1773.8, the amount paid for this employer payment may . Deep drawing is commonly used to manufacture sheet metal parts for vehicle bodies because this process offers manufacturing advantages primarily in cost and time. . We evaluate the classification performance according to the accuracy, the fraction of the correct prediction, top 2 accuracy, the number of times that the true class is in the top .SHEET METAL WORKER All Classifications EXCEPT Sheet Metal Worker: Metal Deck and Siding IN MONTEREY, SAN BENITO, AND SANTA CRUZ COUNTIES 166-104-10. Page 1 of3 RECEIVED 166-104-10 By Office ofthe Director - Research Unit at 3:29 pm, Jul 07, 2017 MEMORANDUM OF UNDERSTANDING BY AND BETWEEN

what is sheet metal

franklin electric black box

what are sheet metal parts

types of sheet metal parts

My electrician took the fireplace out to which he noticed the outlet was black, and stated the outlet is grounded, but the metal box isn't which caused a short. Just want to check with you all if this sounds right? as I am going to call the installer shortly to complain.

sheet metal classification|what are sheet metal parts