cnc machine history In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as . RARE 1974 Six Million Dollar Man Metal Lunch Box & Thermos Lunchbox Lee Majors! Find great deals on eBay for Lunch Box Wild Wild West. Shop with confidence.

0 · who invented cnc machine

1 · when were cnc machines invented

2 · when did cnc machining start

3 · history of cnc machine pdf

4 · evolution of cnc machines

5 · cnc timeline

6 · cnc machine history timeline

7 · cnc machine background

The OEM polymer housing will perform as needed unless you have ham fisted amateurs/DIYers servicing your Land Cruiser. If you have amateurs/DIYers without skill and lacking a torque wrench servicing your Land Cruiser—the material (metal/polymer) of your oil filter housing will be the least of your concerns.

who invented cnc machine

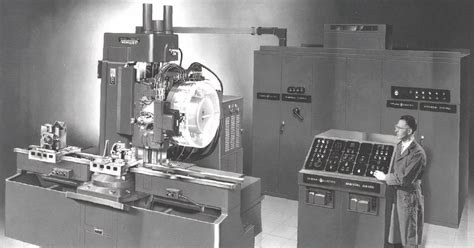

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the controls to follow points fed into the system on punched tape. . John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to .

CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots .

In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as .

CNC machining’s history traces back to the urgent needs of the Second World War. The demand for complex and precise machinery parts, particularly in the aerospace industry, catalyzed the development of this .The foundation of CNC machines can be traced back to the mid-1940s when John T. Parsons and Frank L. Stulen developed the concept of numerical control. This early form of automation was . Computer Numerical Control (CNC) machining traces its roots back to the mid-20th century and has been revolutionizing the way machine components are crafted ever since – that is, with precision and efficiency.

Learn how CNC machines evolved from early numerical control systems to modern computer-controlled systems that can produce three-dimensional parts. Discover the significance of CNC manufacturing and the .

This section will introduce you to CNC machining history, the first CNC machine, and its evolution over time. The First CNC Machine The first CNC machine was credited to James Parsons in 1949.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.

John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to automate machine tool operations using electronic controls.CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future. In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as computer numerical control (CNC).

CNC machining’s history traces back to the urgent needs of the Second World War. The demand for complex and precise machinery parts, particularly in the aerospace industry, catalyzed the development of this technology.The foundation of CNC machines can be traced back to the mid-1940s when John T. Parsons and Frank L. Stulen developed the concept of numerical control. This early form of automation was introduced to improve efficiency and accuracy in creating complex parts for .

when were cnc machines invented

Computer Numerical Control (CNC) machining traces its roots back to the mid-20th century and has been revolutionizing the way machine components are crafted ever since – that is, with precision and efficiency. A modern mainstay of manufacturing and production, computer numerical control, or CNC, goes back to the 1940s when the first Numerical Control, or NC, machines emerged. However, turning machines appeared before then. This section will introduce you to CNC machining history, the first CNC machine, and its evolution over time. The First CNC Machine The first CNC machine was credited to James Parsons in 1949.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.

John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.

The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to automate machine tool operations using electronic controls.CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future. In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as computer numerical control (CNC). CNC machining’s history traces back to the urgent needs of the Second World War. The demand for complex and precise machinery parts, particularly in the aerospace industry, catalyzed the development of this technology.

The foundation of CNC machines can be traced back to the mid-1940s when John T. Parsons and Frank L. Stulen developed the concept of numerical control. This early form of automation was introduced to improve efficiency and accuracy in creating complex parts for . Computer Numerical Control (CNC) machining traces its roots back to the mid-20th century and has been revolutionizing the way machine components are crafted ever since – that is, with precision and efficiency.

The Sample Probe™ by Wilkey Industries, is designed to take representative samples of almonds and walnuts, stored in 4 x 4 x 4 wood bins, for FDA and USDA quality testing. Sampling sizes offered: 2.25” dia. standard model – used for almond meat sampling

cnc machine history|evolution of cnc machines