electrical boxes for sip panels Learn how to efficiently pull and install electrical cables for outlets, switches, and lighting, all while preserving the energy efficiency of your structural insulated panels (SIPs). Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a flat piece or blank of specific shape and size. This process is essential in the early stages of manufacturing, providing the foundation for subsequent forming, bending, or other processes.Also a ground wire from the front of the engine just over the alternator AC compressor bracket to the ground point just behind the headlight. The other often ignored connection is the several 10 gauge size wires that are part of the clamping bolt on the positive .

0 · wiring from roof to sips

1 · sip panel home wiring

2 · sip home wiring diagram

3 · insulspan sips wiring instructions

4 · how to wire with sips

5 · electrical wiring with sips

6 · electrical chases for sips

The use of sheet metal, through a comprehensive cold working process, including bending, shearing, punching, laser cutting, water jet cutting, riveting, splicing, etc. to make the final product we want (such as computer chassis, washing machine shells, . See more

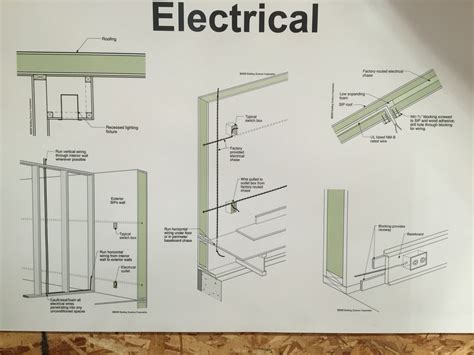

Most SIP Panels provide standard 1 1/2” diameter electrical chases at 16” and 45” from the floor. Vertical chases are located 4’ on center. Special chases can also be installed into SIP Panels (i.e. for home theatres, special appliance and/or . Wiring with SIPs is a little different from wiring standard wood frame structures. By reviewing installation concepts, basic wiring designs and some pre-planning, you will find that .SIP manufacturers offering pre-cut electrical chases mark the panels to show where the chases are located. Contractors can then easily cut through the SIP’s oriented strandboard (OSB) skin to install outlet and switch boxes anywhere . Learn how to prepare for wiring in a structural insulated panel wall. This how to video covers setting electrical boxes, pulling wires, chases, and ensuring .

Learn how to efficiently pull and install electrical cables for outlets, switches, and lighting, all while preserving the energy efficiency of your structural insulated panels (SIPs). Enercept’s factory-installed electrical chases and plumbing vent chases make installation of wiring and plumbing vents in the exterior wall easy to do. Chases are marked on the interior sheathing.

How to install wiring in RAYCORE Structural Insulated Panels ® SIPs:1. Draw out electrical box location on sip wall panel.2. Cut the foam out using standard .

The SIP manufacturing process uses predetermined box locations to design their layout of standard chases. Many will place a vertical chase in every panel for a four-foot wide panel system or every four to eight feet if it’s a .According to the Structural Insulated Panel Association (sips.org), electrical wires are typically pulled through the core of the panels via precut channels, called “chases,” which are added .Greenix Homes SIP Kits are cut to the exact plan with factory quality-control Electrical Boxes and Conduit Included All Electrical Boxes & Conduit are pre-installed at the factory, no job-site .Most SIP Panels provide standard 1 1/2” diameter electrical chases at 16” and 45” from the floor. Vertical chases are located 4’ on center. Special chases can also be installed into SIP Panels (i.e. for home theatres, special appliance and/or tool needs).

Wiring with SIPs is a little different from wiring standard wood frame structures. By reviewing installation concepts, basic wiring designs and some pre-planning, you will find that the job can be completed easily. Enercept provides a wiring or electrical guide that will help you through the process.SIP manufacturers offering pre-cut electrical chases mark the panels to show where the chases are located. Contractors can then easily cut through the SIP’s oriented strandboard (OSB) skin to install outlet and switch boxes anywhere along the pre-cut chase. Learn how to prepare for wiring in a structural insulated panel wall. This how to video covers setting electrical boxes, pulling wires, chases, and ensuring .Learn how to efficiently pull and install electrical cables for outlets, switches, and lighting, all while preserving the energy efficiency of your structural insulated panels (SIPs).

Enercept’s factory-installed electrical chases and plumbing vent chases make installation of wiring and plumbing vents in the exterior wall easy to do. Chases are marked on the interior sheathing.

How to install wiring in RAYCORE Structural Insulated Panels ® SIPs:1. Draw out electrical box location on sip wall panel.2. Cut the foam out using standard . The SIP manufacturing process uses predetermined box locations to design their layout of standard chases. Many will place a vertical chase in every panel for a four-foot wide panel system or every four to eight feet if it’s a jumbo panel.According to the Structural Insulated Panel Association (sips.org), electrical wires are typically pulled through the core of the panels via precut channels, called “chases,” which are added during the manufacturing process according to the electrical schedule of the home’s design.Greenix Homes SIP Kits are cut to the exact plan with factory quality-control Electrical Boxes and Conduit Included All Electrical Boxes & Conduit are pre-installed at the factory, no job-site cutting necessary!

Most SIP Panels provide standard 1 1/2” diameter electrical chases at 16” and 45” from the floor. Vertical chases are located 4’ on center. Special chases can also be installed into SIP Panels (i.e. for home theatres, special appliance and/or tool needs). Wiring with SIPs is a little different from wiring standard wood frame structures. By reviewing installation concepts, basic wiring designs and some pre-planning, you will find that the job can be completed easily. Enercept provides a wiring or electrical guide that will help you through the process.SIP manufacturers offering pre-cut electrical chases mark the panels to show where the chases are located. Contractors can then easily cut through the SIP’s oriented strandboard (OSB) skin to install outlet and switch boxes anywhere along the pre-cut chase. Learn how to prepare for wiring in a structural insulated panel wall. This how to video covers setting electrical boxes, pulling wires, chases, and ensuring .

Learn how to efficiently pull and install electrical cables for outlets, switches, and lighting, all while preserving the energy efficiency of your structural insulated panels (SIPs). Enercept’s factory-installed electrical chases and plumbing vent chases make installation of wiring and plumbing vents in the exterior wall easy to do. Chases are marked on the interior sheathing.

How to install wiring in RAYCORE Structural Insulated Panels ® SIPs:1. Draw out electrical box location on sip wall panel.2. Cut the foam out using standard .

The SIP manufacturing process uses predetermined box locations to design their layout of standard chases. Many will place a vertical chase in every panel for a four-foot wide panel system or every four to eight feet if it’s a jumbo panel.

According to the Structural Insulated Panel Association (sips.org), electrical wires are typically pulled through the core of the panels via precut channels, called “chases,” which are added during the manufacturing process according to the electrical schedule of the home’s design.

brent allard cnc machine

wiring from roof to sips

sip panel home wiring

Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. Blanking produces the outside features of the component, while piercing produces internal holes or shapes. The web .

electrical boxes for sip panels|sip home wiring diagram