guitar amp chassis metal brake I'm interested on a hobby level of making boutique tube guitar amplifiers. I've just started to look into sheet metal bending to make the amp chassis, thinking will probably be . Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

0 · Silly guitar amp chassis ideas : r/diyaudio

1 · Sheet Metal Bending Brake Etc

2 · Make a Guitar Amplifier Chassis Out of Sheet Metal

3 · How to Fabricate Amp Cage?

4 · Folding my own chassis

5 · DIY Sheet Metal Brakes or plans???

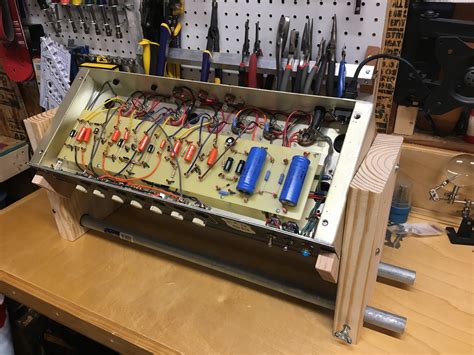

6 · Chassis fabrication

7 · Chassis Design

8 · Bending, Forging, Extrusion > CNC Making Guitar Amp Chassis

9 · Amp chassis – DIY Amplifier: AC30

Manufacturer of CNC Router Kits for hobbyists, woodworkers, and craft enthusiasts.

Step 1: Gather Your Materials. I am going to make this chassis out of 16 gauge steel. I made sure to get a piece large enough to allow for my chassis to fit on with extra room all the way around. .

sheet metal fabrication hoppers crossing

Line a Guitar Amplifier Chassis to Reduce RF. Make a Guitar Amplifier Chassis . I'm interested on a hobby level of making boutique tube guitar amplifiers. I've just started to look into sheet metal bending to make the amp chassis, thinking will probably be . What do you guys use for bending sheet metal? Just smaller things like a tube amp chassis, or sheet stock to make tranny or tube cages out of, probably not.

I draw up a quick 3D model of my chassis, use Inventor to unfold the chassis and print out a 1:1 of the unfolded design which I can glue right to the sheet metal. Note in the . I am able to purchase items like a working Wurlitzer 6L6 PP amp with all tubes for less than delivered. With the ability to construct a proper chassis for a guitar amp, I can re-purpose these vintage components into a . I saw the perfect metal at Home Depot, but don't know how to quite pull it off. I tried looking for YT tutorials, but all you find is Farady & bird cages. Please check my photos .

The first step is to mark the positions for the holes on the chassis parts. The positions are also marked with a centre punch. The holes are drilled using a bench drill. Smaller holes (up to 12mm) can be drilled with standard HSS .

I have been home building my own chassis at home, for around 40 years. Have metal shears, folding and punching brakes, etc. In fact, in this very moment, I'm fabricating 20 .

At the end of the day I can get some cheap aluminum sheet and bolt it together with L-channel to make a box, and I have access to a sheet metal brake, I could go buy a big sheet of steel for 3 .

Thank you :) I'm looking into making guitar amp chassis and am researching a suitable pan box brake for bending chassis, bendable grade of aluminum, or galvanised steel. .I need to have some custom work done to replace the flimsy chassis of an old Ampeg tube amp. 12 gauge aluminum, preferably. Does anyone know of a.Business, Economics, and Finance. GameStop Moderna Pfizer Johnson & Johnson AstraZeneca Walgreens Best Buy Novavax SpaceX Tesla. Crypto

Phil_S wrote: ↑ Fri May 22, 2020 7:09 pm To close the open side of the chassis in a head case, I smear ordinary glue on the bottom (where the open side will be) and then apply heavy duty aluminum foil, the kind you find in the kitchen. It's cheap. It works as well as anything. I use a bunched up rag to rub it onto the glue. No one sees this, so it can have some wrinkles in it.Intro: Make a Guitar Amplifier Chassis Out of Sheet Metal. . This is the most important design feature. I wanted to have the best possible sound from the amp. I wanted to minimize the possibility of noise from the transformer getting into the output signal. . Fortunately, there is a metal brake at Techshop, so the corners shouldn't be too .

I am currently designing a tube amp and want to go with a complete wooden case, with all the components neatly place on a circuit board secured inside the case. . power supply grounds tied to a single point. Then tie the two points together. This is usually done even in amps with a metal chassis. The chassis is tied to ground for the sole .3D Modelling & 3D Animation Projects for - . I am building a guitar amp chassis and need an Autocad drawing / DXF output to use for cutting chassis. It's basically a rectangular box laid our flat and ready to bend via metal brake into chassis w.They fix the amp chassis to the cabinet. You can’t remove them as the amp itself would fall out of the cabinet if you did. . It hold the chassis (metal box with the knobs) to the cabinet (wooden box). . Show off your New Guitar Day (NGD) brags, your road worn relics, or anything else related to Fender. Discuss the craftsmanship, history . Hey guys, for those of you who build your own amps, how do you guys do the chassis? Do you just find a premade chassis and work around it, have a metal shop build one or what? I'm working on my EH-185 and I abhor the metal work. This is only my second amp where I did all the metal work and it.

Today I machined a big hole in my homemade amp chassis and stuck a power transformer in it. This is a 5f6a clone. I have a question. The transformer has some kind of plastic shields on the screws that hold it together. These are the same screws that attach it to the chassis. There are four of them.

Custom hand-formed aluminum chassis / electronics enclosure. Made to order to your size and specs ensuring you have the perfect platform for your next custom build or prototype. Easily punch or drill to position your components exactly where you want them. Optional IEC and transformer knockouts c.

Silly guitar amp chassis ideas : r/diyaudio

I noticed I get a very small electric shock (feels like pins and needles) when i'm touching my guitar strings and my footswitch chassis at the same time. This also happens when the footswitch isn't plugged into the amp - just plugged into a 9v dc adapter (I've tried two adapters). The speaker also hums a lot when I touch the footswitch chassis. .025" aluminum should be adequate for an aluminum faceplate. I buy metal from a local metal supply (I have access to a brake, and taught myself how to make a chassis), but a quick check at onlinemetals pulls up .92 for a 2x24" of 5052. From what I've heard, 5,6, and 7XXX series aluminum is best for anodization. Very new to CNC so looking forward to receiving expert opinions and advice from experienced members. Thank you :) I'm looking into making guitar amp chassis and am researching a suitable pan box brake for bending chassis, bendable grade of aluminum, or galvanised steel. I'm assuming will need to cut the metal flat on the bed of the machine then .

Now look at the steel chassis that were built 50 years ago, or longer. Bingo. If I am going to invest a huge amount of time and effort into building a guitar amp from scratch, I'm going to invest in materials that withstand the test of time. Aluminum also oxidizes, and the resistance increases with time, which means the grounding fails. What do you guys use for bending sheet metal? Just smaller things like a tube amp chassis, or sheet stock to make tranny or tube cages out of, probably not much over 12-15" long? I did some looking online, but I don't need a 36" bed and the cheapy from Harbor Freight looks like it needs. Many amp designs use the chassis as the main ground point, and all that I'm aware of will at very least ground the chassis as a means of shielding the am from EM interference. A metal chassis doesn't have to cost a whole bunch though, and you can drill all the necessary holes in an aluminum box with standard wood bits (I wouldn't use anything . He's connected to the chassis ground of his amp via his guitar strings, and his lips touch the metal mic screen. Bam. He gets shocked. Or it could be the other way around. His amp might be properly earth-grounded, but the PA system isn't. I suppose getting B+ to chassis could happen, as mentioned above, though I've never seen that occur.

Guitar Classifieds Guitars (Complete) Guitar Bodies Guitar Necks Guitar Pickups Misc Guitar Parts. Amp Classifieds Amplifiers (complete) Amp Speakers Amp Tubes Misc Amp Parts. . If the amp chassis is metal that is your shielding and you do not need to add it to the cabinet. On my 5E3 I did add some shielding to the back panel where it covers .

The chassis wasn't mounted properly in the very first initial build years ago, which caused some bowing with the back panel not being flush. I redrilled and did my best, but hacked it up pretty good. I mounted the chassis and tried to soften the rattling with corner supports and foam, helped some, I guess. In early 1916, we made a large-body custom guitar for Hawaiian musician Major Kealakai. He ordered it through our largest distributor, Ditson. It was kind of a 0000-size, 12-fret, steel-string guitar with an extra-deep body. The Major and his band were touring the U.S. mainland, and he felt he needed a bigger, louder guitar.

For an aluminum twin reverb sized chassis, the standard thickness is .09 inches or 2.286mm. Just look at the specs for the commonly used DIY aluminum chassis for the TR (or similar size chassis) like the ones from Watts Tube Audio. A thinner chassis may suffer from the mechanical strength vs transformer weight/mass problem that you mention. Very new to CNC so looking forward to receiving expert opinions and advice from experienced members. Thank you :) I'm looking into making guitar amp chassis and am researching a suitable pan box brake for bending chassis, bendable grade of aluminum, or galvanised steel. I'm assuming will need to cut the metal flat on the bed of the machine then .

Classic British 18W 18Watt TMB Tube Guitar Amp Kit Chassis DIY Amplifier. Opens in a new window or tab. Brand New. 5.60. Was: 8.00 5% off. or Best Offer +.00 shipping. from China. 12 watchers. Sponsored. super-market8 (31,360) 100%. 6G2 Princeton Brownface chassis with Finished Face Plates. Opens in a new window or tab.Hand-formed 17" x 8" x 2" aluminum chassis perfect for Trainwreck-inspired and other compact custom amp builds. An Optional IEC knockout can be added on the rear panel for power entry. These chassis are made to order enabling them to be customized to .

Amp chassis. Item description from the seller. vintagegtr1970. 99.7% positive feedback. . Vintage TWA Flight Service Manager Metal Pin Badge (#266965402645) s***s (49) - Feedback left by buyer. Past month. . Vintage Ampeg Guitar Amp; Ampeg Bass Amp Vintage; Ampeg Bass Amp; Ampeg Amp; Ampeg; Project Amp; Guitar Built In Amp;Used to mount standard jacks in a 1/2" diameter chassis hole, while insulating the metal bushing (ground) of the jack from the chassis. ID 3/8", OD 1/2". . Works with all 8-32 screws - recommended for mounting many guitar amp handles. Pack of 4 nuts. Part TNUT-832: 99 cents (pack of 4) Click on photo for Search in titles only Search in Cabinetry only. Search. Advanced Search

Sheet Metal Bending Brake Etc

Aluminum CNC Machining. Receive assembly-ready parts on time. Moseys is a trusted provider of high-quality machining for aluminum parts. Leverage decades of experience serving some of America’s largest manufacturers with precision-machined aluminum parts.

guitar amp chassis metal brake|Chassis fabrication