what is the sheet metal • "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See more Most precision turned parts products boast high quality and low MOQs with direct prices from factory, covering high precision turning parts, aluminum base with hard anodized surface .

0 · what is sheet metalworking

1 · types of metal sheets

2 · steel sheet price per kg

3 · sheet metal types list

4 · sheet metal types and grades

5 · sheet metal size chart

6 · sheet metal characteristics

7 · metal sheets at screwfix

Explore & source all the CNC replacement parts you need to keep your machine in top working order. Connect with us if you need help finding the correct part.

what is sheet metalworking

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or . See moreHand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The . See more

types of metal sheets

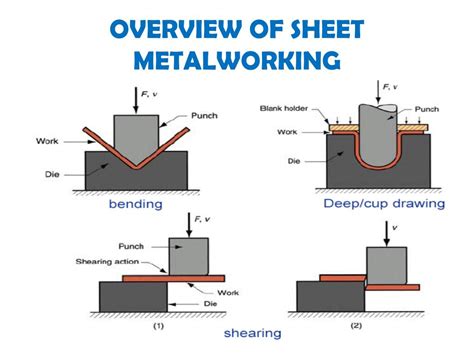

BendingThe equation for estimating the maximum bending force is,$${\displaystyle F_{\text{max}}=k{\frac {TLt^{2}}{W}}}$$,where k is a factor taking into account several parameters . See more

Fasteners that are commonly used on sheet metal include: clecos, rivets, and sheet metal screws. See more

• "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See more

Stainless steelGrade 304 is the most common of the three grades. It offers good corrosion resistance while . See more

The use of sheet metal, through a comprehensive cold working process, including bending, shearing, punching, laser cutting, water jet cutting, riveting, splicing, etc. to make the final product we want (such as computer chassis, washing machine shells, . See more• Circle grid analysis• Corrugated galvanised iron, also known as Corrugated Sheet Metal• Diamond plate• Forming limit diagram See more

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than .

steel sheet price per kg

Sheet metal fabrication is the process of turning flat sheets of steel or aluminum into metal structures or products, by cutting, punching, folding, and assembling. Sheet metal can be cut, bent, or stretched into nearly any shape, which is .Sheet metal is an industrial process that forms thin, flat pieces of metal, such as steel and tin, into coils. In the U.S., the thickness of sheet metal is typically specified by its gauge, which ranges . Hydroforming: Hydroforming is a shaping process that uses hydraulic pressure to press the die upon the metal sheet. In this process, the metal sheet is pressed by the die to form the desired shape at room temperature. Hydroforming is often used for ductile materials. Roll Forming: In the roll forming process, a long metal sheet is passed .The sheet metal thickness of most durable cars is usually between 20 gauge to 28 gauge. This is because thicker sheet metal is more resistant to bending and denting. Additionally, it can also help to improve fuel efficiency and reduce noise levels. What is the Best Type of Sheet Metal for a Car? A car may consist of different types of sheet metal.

It's probably been mentioned before but sheet metal will always be thinner than the standard guage thickness specified. It almost always will be at the lower range of the tolerance. As it is sold by the pound and based on the pounds per square foot using the standard gauge thickness. So a 4x8 sheet will have a theoretical weight but will .Sheet Metal is arguably one of best component deals at outpost. If we give 100 metal the value of 7 scrap and 1 HQM the value of 6 scrap. The total recycled value of would be 21. Quite close to the outpost cost of 30. Sheet metal is the next in line. The thickness of sheet metal starts from 0.5 mm and goes up to 6 mm. Anything above that is a metal plate. The thin sheet metal is easy to form, while still providing great strength. At a relatively cheap price, it makes a great fit for most engineering purposes. That is why we see it everywhere around us.

If you have a set of calipers you can measure the thickness of the existing metal and then order what you need. Here's some of the common gauges and corresponding thickness of sheet steel: GA. Thickness 12 - 0.1046 13 - 0.0897 14 - 0.0747 15 - 0.0673 16 - 0.0598 17 - 0.0538 18 - 0.0478 19 - 0.0418 20 - 0.0359 21 - 0.0329 22 - 0.0299

When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the

Be aware that this metal will not likely be ordinary mild steel. Comment. Post Cancel. dcsound. Senior Member. Join Date: Jun 2004; Posts: 103; Share Tweet #4. 03-30-2005, 05:58 PM. The vehicle I'm planning to work on is a 1997 Jeep Grand Cherokee. I'm trying to do the work myself or myself with a few friends as a learning experience and to try . Sheet metal plays a pivotal role in various industries, from construction and automotive to artistry and home improvements. Ensuring you select the right sheet metal gauge, or thickness, is crucial for the integrity, durability, and efficiency of the final product. The purpose of this guide is to delve into the complexities of the sheet metal . Sheet metal is a general category for metals that are approximately 0.018 to 0.250 in thickness. The thickness of sheet metal is often designated by a gauge rather than inches or millimeters. However, different types of material will have a slightly different gauge system to designate their thicknesses. Aluminum, steel, galvanized steel .Sheet Metal Workers Local 2 Area 2 Office: 1316 Fredrick St. Joseph, MO 64501 site: sheetmetal2.org: Phone: 816.254.8021 Email: Contact Person: Gene Kelley: Sheet Metal Workers Local 2 - Area 6 Office: 5990 SW 28th Street Topeka, KS 66614 site: sheetmetal2.org: Phone: 816.254.8021

5. Sheet Metal Bending Collisions. Whether it’s an asteroid, a motor vehicle, or a sheet metal part, collisions really aren’t a good thing. In the world of bending, a collision occurs when the material to be bent contacts any surface other than the dies.ANSI, the American National Standards Institute, has accredited SMACNA as a standards-setting organization. SMACNA standards and manuals address all facets of the sheet metal and HVAC industry – including duct construction and installation, indoor air quality, energy recovery, roofing and architectural sheet metal, welding, and commissioning.

Sheet metal screws are widely used in various applications, ranging from automotive, construction, and HVAC industries. They are commonly used to fasten roof panels, gutters, air conditioning ducts, electrical boxes, and other materials. The most critical aspect when choosing a sheet metal screw is ensuring it is tailored for the specific . Sheet metal is a material that has gotten applications in different industries – ranging from automotive to aerospace and consumer electronics manufacturing. And, for each industry, most manufacturers tend to require . A sheet metal shearing machine is a machine used in metal fabrication industry for cutting metal plates into various desired shapes and sizes. The components of a shearing machine are blades, pulleys, baffles, and an . The position of the neutral layer in sheet metal depends on specific material properties, such as ductility. Assuming the distance between the neutral sheet metal layer and the surface is “t,” that is, the depth from the surface of .

custom machined parts online

The Sheet of Metal is an item in The Escapists and The Escapists 2. Can be purchased from fellow inmates, found in desks or stolen from the Metal Shop. The Sheet of Metal is a crafting component. It is also a weak weapon in The Escapists 2. Additionally, it can be placed in the press in the Metal Shop [TE1] / Blacksmith [TE2] job in order to create a License Plate [TE1] / .

Sheet Metal Thickness in Different Parts of a Vehicle. Different parts of a vehicle have distinct requirements when it comes to sheet metal thickness. Body panels, for example, may require thinner sheets for aesthetics and weight considerations, while the chassis demands thicker sheets for structural strength. Sheet metal setback refers to the distance from the bend line to the point where the metal starts to bend. It is also described as the difference between the mold line length and the flange length. Also is a crucial factor in sheet metal fabrication.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. To achieve the required sheet metal tolerance in sheet metal part design guidelines, manufacturers must use precise machinery during production.

sheet metal types list

Sheet metal bending is a forming operation where sheets are deformed plastically to change their shape. During sheetmetal bending, the material is stressed beyond its yield strength but below the ultimate tensile strength. After bending a sheet metal part, the total length of sheet metal is more than the flat length.The Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) is an international trade association representing 3,500 signatory contracting firms with more than 100 chapters throughout the United States, Canada, Australia, and Brazil. A leader in promoting quality and excellence in the sheet metal and air conditioning industry, SMACNA has offices in .

sheet metal types and grades

Sheet Metal Worker Salaries by State. What is the average annual salary for a Sheet Metal Worker job by State? See how much a Sheet Metal Worker job pays hourly by State. Washington is the highest paying state for Sheet Metal Worker jobs. Florida is the lowest paying State for Sheet Metal Worker .What is Sheet Metal? Sheet metal is an industrial process that forms thin, flat pieces of metal, such as steel and tin, into coils. In the U.S., the thickness of sheet metal is typically specified by its gauge, which ranges from 30 gauge to about 7 gauge. Sheet metal is a very useful material that can be used for a wide variety of applications. With that being said, you will usually need to cut this building material to the right size and shape for your exact project. There are many different ways to cut sheet metal out there. Today, we want to discuss the best ways to cut this material.Here's a picture .At the bottom of the picture is a ~1 inch tall I beam. Above that is a broad flat metal sheet with recessed strips perpendicular to the I beam. It looks like the sheet is several feet wide before another recessed strip on the other side. There appear to be several of them running in parallel along the width of my condoceiling.

sheet metal size chart

To order replacement parts for your Haas CNC machine, please use our distributor locator tool below to find your local Haas Factory Outlet. Your local HFO will be able to find and deliver your factory replacement parts, based on the specific model and year of .

what is the sheet metal|steel sheet price per kg