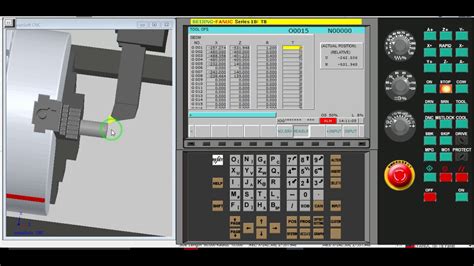

ai for cnc machining Intelligent machine tool can be presented using the applications of AI in CNC machining operations in order to present the autonomous optimization and decision-making, . $158.39

0 · mechanical ai tools

1 · cnc programming with ai

2 · cnc programming ai bot

3 · artificial intelligence in cnc programming

4 · ai nc programming

5 · ai in cnc manufacturing

6 · ai for machine shops

7 · ai cnc programming software

These boxes are located in two mirror image bath rooms and the outlets are in the same spot on both walls, considered back to back. The code does not allow back to back's .

Artificial Intelligence (AI) is revolutionizing CNC machining by enhancing precision, efficiency, and automation. AI algorithms optimize cutting paths, predict machine maintenance, and enable real-time adjustments, . Intelligent machine tool can be presented using the applications of AI in CNC machining operations in order to present the autonomous optimization and decision-making, .

AI can analyze CAD models and automatically generate CNC machining G-Code, significantly reducing manual programming time and errors. For example, Autodesk’s Fusion 360 integrates AI technology to automatically . Artificial Intelligence (AI) is revolutionizing CNC machining by enhancing precision, efficiency, and automation. AI algorithms optimize cutting paths, predict machine maintenance, and enable real-time adjustments, leading to reduced waste, faster production times, and .

AI is transforming CNC programming and machining by streamlining processes, improving efficiency, precision, and productivity in manufacturing. AI-driven solutions can rapidly generate CNC programs, optimize toolpaths, and predict potential machining issues. Intelligent machine tool can be presented using the applications of AI in CNC machining operations in order to present the autonomous optimization and decision-making, and autonomous control and execution during machining operations. AI can analyze CAD models and automatically generate CNC machining G-Code, significantly reducing manual programming time and errors. For example, Autodesk’s Fusion 360 integrates AI technology to automatically identify part features and generate corresponding machining paths. AI systems in CNC machining can automate setup procedures, tool changes and even adapt to new designs with minimal human intervention. This results in faster production cycles and a notable reduction in human error.

AI systems in CNC machining can automate setup procedures, tool changes and even adapt to new designs with minimal human intervention. This results in faster production cycles and a notable reduction in human error.

CAM Assist is an AI that understands the physics and rules of CNC machining, works at full effectiveness out of the box, and receives new capabilities added monthly enabling it to program more components with faster cycle times and better process robustness.

Lambda Function's focus is on enabling machining autonomy by augmenting CNC programmers & operators with AI. Our software combines decades of CNC machining domain knowledge with the latest advancements in computer science and artificial intelligence to .AI in CNC machining helps deliver on two fundamental goals: efficiency and productivity. As data is generated during production, AI analyzes it so the engineers and skilled operators can adjust the machine, or remove impediments that slow it down, to operate at peak efficiency. We take a look at two areas that are expected to really make an impact within CNC systems: machine learning and artificial intelligence, or “AI.” Artificial intelligence—whether from software-based algorithms, smart probes or voice command—is one half . Artificial Intelligence (AI) is revolutionizing CNC machining by enhancing precision, efficiency, and automation. AI algorithms optimize cutting paths, predict machine maintenance, and enable real-time adjustments, leading to reduced waste, faster production times, and .

AI is transforming CNC programming and machining by streamlining processes, improving efficiency, precision, and productivity in manufacturing. AI-driven solutions can rapidly generate CNC programs, optimize toolpaths, and predict potential machining issues. Intelligent machine tool can be presented using the applications of AI in CNC machining operations in order to present the autonomous optimization and decision-making, and autonomous control and execution during machining operations. AI can analyze CAD models and automatically generate CNC machining G-Code, significantly reducing manual programming time and errors. For example, Autodesk’s Fusion 360 integrates AI technology to automatically identify part features and generate corresponding machining paths. AI systems in CNC machining can automate setup procedures, tool changes and even adapt to new designs with minimal human intervention. This results in faster production cycles and a notable reduction in human error.

AI systems in CNC machining can automate setup procedures, tool changes and even adapt to new designs with minimal human intervention. This results in faster production cycles and a notable reduction in human error.CAM Assist is an AI that understands the physics and rules of CNC machining, works at full effectiveness out of the box, and receives new capabilities added monthly enabling it to program more components with faster cycle times and better process robustness.Lambda Function's focus is on enabling machining autonomy by augmenting CNC programmers & operators with AI. Our software combines decades of CNC machining domain knowledge with the latest advancements in computer science and artificial intelligence to .

AI in CNC machining helps deliver on two fundamental goals: efficiency and productivity. As data is generated during production, AI analyzes it so the engineers and skilled operators can adjust the machine, or remove impediments that slow it down, to operate at peak efficiency.

mechanical ai tools

cnc programming with ai

cnc programming ai bot

artificial intelligence in cnc programming

ai nc programming

Buy GE T050N Twist Lock Power Inlet, 120/240 VAC, 50 A, NEMA 3R, Galvanized Steel: Electronics - Amazon.com FREE DELIVERY possible on eligible purchases

ai for cnc machining|artificial intelligence in cnc programming