home built sheet metal brake Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until . Business profile of Twickler Raymond Roofing & Sheet Metal Inc, located at 827 Cadiz St., New Orleans, LA 70115. Browse reviews, directions, phone numbers and more info on Twickler Raymond Roofing & Sheet Metal Inc.

0 · small metal bending brake

1 · sheet metal bending brake plans

2 · homemade sheet metal press brake

3 · homemade sheet metal bending brake

4 · homemade sheet metal bender plans

5 · homemade metal brake bender

6 · home made sheet metal folder

7 · diy sheet metal bender plans

$48.98

Need to bend sheet metal? It's really easy to build a simple DIY metal brake!!TOOLS & SUPPLIES:https://kit.co/iliketomakestuff/my-metalworking-toolshttps://k. The Sheet Metal Brake I always wanted: 36" glory, cantilever locking mechanism, adjustable fingers, weighs as much as I do! (NOTE: . LINK TO FREE PLANS BELOW! Need to bend sheet metal? Making one yourself is cheap & easy Next episode we are tackling a new project that requires a metal brake, off the shelf machines are pricey and seem a little on. Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding, eaves, air conditioning ductwork, and others. .

Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until .With your DIY metal brake complete, it's time to test it out. Start by clamping down a sheet of 18-gauge (1 mm thick) steel and bending it to 90 degrees. If everything is aligned properly, you .

A few weeks back, I was working on a project that required bending some thin sheet metal and was having some trouble. While on a Google hangout with my patreon supporters, my friend Evan mentioned making a .DIY Sheet Metal Bender Brake Fully Modified: At a previous instructable, we had seen the build of a simple version, Sheet Metal Brake. The brake works pretty good but, has some limitations. The thickness of bending material can't be .Build your own brake to simplify working with sheet metal. Unfortunately for the do-it-yourself type, metal brakes are often expensive, and it is impractical to buy one for use on only a few projects.

In this video I show how to build a metal brake with a 72+ inch working capacity. The unit as shown is approximately 82" tip to tip, has a working surface height of 33.5" and .Boyd Bilt Fabrication is an industry-leader for the highest quality precision sheet metal brakes, spring smashers, pull down rigs, and much more! We strive to manufacture the highest quality products that meet the needs of our .

This Boyd-Bilt 10 foot heavy duty sheet metal brake is ideal for race car bodies, HVAC work, and more. With features such as a cam-lock design, bronze hinge bushings, adjustable tension bars, adjustable counterweights, and 1/2 inch . Metal saw, (hack saw, Sawzall, bandsaw) A welder capable of welding 1/4-inch steel The channel forms the base for the brake; you can build a stand for it or mount it on a bench vice temporarily. One piece of angle forms . In this video I show how to build a metal brake with a 72+ inch working capacity. The unit as shown is approximately 82" tip to tip, has a working surface h.

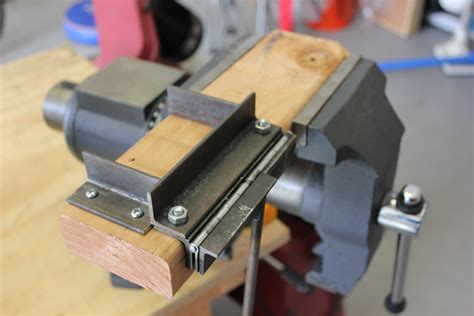

Drawing from numerous online sources, [makjosher]’s brake is built from 1/8″ steel bar, as well as 1/8″ steel angle. The angle is secured to a 3/4″ wood mounting plate. Need to bend sheet metal? Making one yourself is cheap & easyNext episode we are tackling a new project that requires a metal brake, off the shelf machines a.Home built Sheet Metal Brake. 5' wide capacity. I built 2 complete ductwork systems with 26 gauge galvanized metal. It may not be pretty--but it works! Thought I'd better update my ad to make it clear that the rolling table is not included. The brake is attached to my table, but a buyer will need to provide their own table to bolt the brake to.

This Boyd-Bilt 8 foot heavy duty sheet metal brake is ideal for race car bodies, HVAC work, and more. With features such as a cam-lock design, bronze hinge bushings, adjustable tension bars, adjustable counterweights, and 1/2 inch plate steel construction, Boyd-Built brakes are among the highest quality fabricated sheet metal brakes on the market.Build a Sheet Metal Brake: I love building tools. There's been more than a few times I've needed to bend metal and I've resorted to clamping 2x4s together and using a hammer. I needed better. I saw a how to on making a metal brake and wanted to make a few modifications. This. Next you will need an ~4″x8″ piece of sheet metal ~1/8″ thick to attach the three bottom pieces of angle iron to. Also you will need three pieces of angle iron similar in length and thickness to what you used for the top die. . Here are some pictures of my home built press brakes. The non painted one was version one and the blue one is . The project came about simply because [Bob] needed to bend 42″ sections of flashing, and couldn’t find a decent deal on a sheet metal brake above 36″ wide. The build starts with some angle .

Let's take a closer look at my homemade 48" sheet metal bending brake. I explain how it was built, what materials I used and also discuss important design re.

The Boyd BB-0816 Sheet Metal Brake is are constructed with both upper and lower heavy duty tie rods that are tig welded. This robust all-steel craftsmanship ensures a lifetime of fast and precise bends. All Boyd brakes include (2) counterweights, repeat bend stop, and a removable angle bar. They are backed with a limit Phillip Thomas. We’ve poked at bending sheetmetal in a previous installment of Wrenchin’ Wednesday, but today we’re going to talk about how to build your own sheetmetal brake for the sake of getting crisp, precise edges on custom-fabricated parts.Hammering metal around a form is effective, but can leave behind apprentice marks, leave an inconsistent edge, .

Even the folks we know that build cars for a living, and have a sheet metal brake, rarely use them for pieces more than 18 inches long. So why not build a DIY Sheet Metal Brake like this for yourself? It seems to bend . This time at the Quick Speed Shop I'm tired of fighting with my junk Harbor Freight sheet metal brake so I did something about it. I built my own, heavy dut. The max useful capacity of this sheetmetal brake is 805mm (at both versions). The sheet metal on demonstration at part3 video is 0.90mm regular galvanized steel, the bending is 5mm from the edges, and I think that is a very good bending. (the smaller the height of bend the most difficult the job for the brake)

small metal bending brake

Constructing a sheet metal brake at home is simple and efficient. For this DIY project, gather the essential materials including an angle iron, square tube, flat stock, and hinge. . Ease your work by creating a homemade brake—a low-cost, easy-to-build device using angle iron and hinges. This contraption is perfect for bending sheet metals .Home shop built sheet metal brake all 5/16” material build weighs about 200 pounds. Has no stand built for table top. I used to bend .032 aluminum sheets, accurate and consistent, nice tight bend, feels like it could easily handle up to 29 gauge steel or galvanized sheets. It will take sheets up to 67-3/4” wide. I built this sheet metal brake to help me create patch panels for my 88 Jeep YJ project. It may not be perfect yet, but it did what I needed so check it out!.

In order to build a car sometimes you need to build your own tools as well. We build a Colin Furze style sheet metal break, and it works. well enough

Make your own 36″ sheet metal brake! (LINK TO PLANS BELOW)My first design: 3 hours from “in my head” to “in my truck.” Not without its flaws: While it did rockers and transmission tunnel on the V8 Firefly “ok,” it really was a piece of poo.. I did a wack of Googling and found an inspirationally cool set of plans that I liked HERE.. I adapted it to suit metal I already had on a .This Boyd-Built 6 foot racer sheet metal brake is ideal for race car bodies, HVAC work, and more. With features such as a cam-lock design, bronze hinge bushings, adjustable tension bars, adjustable counterweights, and plate steel construction, Boyd-Built brakes are among the highest quality fabricated sheet metal brakes on the market. Warranty:What does a Press Brake do? It allows you to make bends in sheet metal and in thicker steel plate. There is nothing overly scientific about how a press brake works. Attached is a sketch showing the main components along with some details below: Main frame - the core of your machine. In essence, this is nothing more than a rectangle made from .About this item. Mini Sheet Metal Brake: The maximum bending width of the box and pan brake is 36 inches (910 millimeters). Upgraded with a 0.31-inch thick blade and reinforced rib design, this product achieves excellent bending results, effortlessly handling 20-gauge low-carbon steel and 14-gauge aluminum bending.

Get the plans: https://www.resystech.com/sheet-metal-brake.htmlCheck out the build article: https://www.resystech.com/howtobuildasheetmetalbrake.htmlI needed.

zulkit junction box abs plastic dustproof waterproof ip65

zv950 junction box

Turner Fabrication is an American turnkey solution contract production facility for precision machined parts and weldments in any quantity. Located in Nacogdoches, Texas on the future I .

home built sheet metal brake|homemade sheet metal bending brake