cnc cutting speed and feed list for machining In this guide, I’ll provide a strategy for calculating your feeds and speeds that uses the formulas for a starting guess and then modifies the numbers based on your specific . $99.99

0 · machining speeds and feeds chart

1 · machining cutting speed chart

2 · cnc speeds and feeds chart

3 · cnc machining speeds and feeds

4 · cnc feed speed calculation

5 · cnc cutting speed formula

6 · cnc cutting speed calculator

7 · cnc cutting speed

$22.74

In this guide, I’ll provide a strategy for calculating your feeds and speeds that uses the formulas for a starting guess and then modifies the numbers based on your specific .

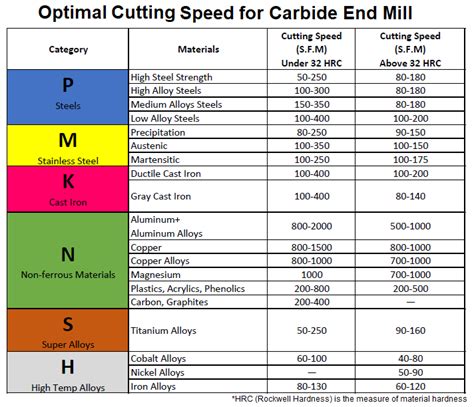

What are speeds and feeds in CNC machining? What are the factors affecting speeds and feeds. Guide to calculating optimal feeds and speeds. Here is the chart with the recommended cutting speed for different materials. 1. Materials: cutting speed for aluminum, brass, bronze, cast iron, . Use Cutting Speeds And Feeds Calculator with simple shop formulas and access a full-featured, industry-leading calculator (free for a . The feeds and speeds chart is a systematic table that includes feed rate and cutting speed for different tooling, work materials, and machining operations. Engineers and CNC .

High Speed Machining: Tool Engagement Angle, Trochoidal Milling, Peeling, and all that Jazz. Dealing With Chatter When Milling: Fixing Chatter via Rigidity or Tuning Speeds and Feeds. .Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 .

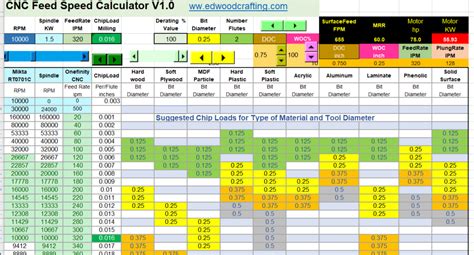

FSWizard is the first and only online speed and feed calculator to consider dozens of variables when calculating Milling, Drilling and Turning Speeds and Feeds. Speeds and Feeds all kinds .The Milling Speed and Feed Calculator automatically calculated the right feed to keep the desired chip load. The calculator works in two stages: Stage 1 – The system calculates the desired maximum chip load according to the cutter type, diameter, and raw material.

In this guide, I’ll provide a strategy for calculating your feeds and speeds that uses the formulas for a starting guess and then modifies the numbers based on your specific operation and machine.

What are speeds and feeds in CNC machining? What are the factors affecting speeds and feeds. Guide to calculating optimal feeds and speeds. Here is the chart with the recommended cutting speed for different materials. 1. Materials: cutting speed for aluminum, brass, bronze, cast iron, magnesium, copper, stainless steel, carbon steel, titanium, etc. 2. Machining process: cutting speed for turning, drilling, reaming, and end milling. 3. Use Cutting Speeds And Feeds Calculator with simple shop formulas and access a full-featured, industry-leading calculator (free for a limited time). Thousands of top manufacturers rely on it daily. They trust the software because it saves them time and money.

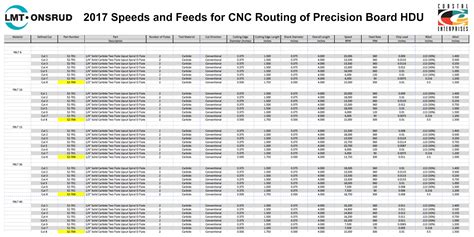

The feeds and speeds chart is a systematic table that includes feed rate and cutting speed for different tooling, work materials, and machining operations. Engineers and CNC operators use this chart to find the best possible values to achieve efficiency, prolong tool life, and achieve accurate results for any specific CNC project.High Speed Machining: Tool Engagement Angle, Trochoidal Milling, Peeling, and all that Jazz. Dealing With Chatter When Milling: Fixing Chatter via Rigidity or Tuning Speeds and Feeds. Micro-Machining: How to avoid breaking those tiny little cutters. Advantages and Pitfalls of Rigid Tapping Long Reach Tools, Thin Walls, and Other Rigidity ChallengesDetermine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. 6061-T6, 5000, 6000, and 7000 series.FSWizard is the first and only online speed and feed calculator to consider dozens of variables when calculating Milling, Drilling and Turning Speeds and Feeds. Speeds and Feeds all kinds of Machining operations. Supports Milling, Drilling, Tapping, and Turning tools. Calculate Cutting Speed (SFM), Chip-Load (ipt), RPM, and Feed-Rate.

CNC Setup is a Balance of Many Factors. I created a Free CNC calculator to help sort a delicate balance between Feed Rates, Chip Loads, Spindle Speed, and Power that go into finding a CNC setup the optimizes finish quality and minimizes the time required.The Milling Speed and Feed Calculator automatically calculated the right feed to keep the desired chip load. The calculator works in two stages: Stage 1 – The system calculates the desired maximum chip load according to the cutter type, diameter, and raw material. In this guide, I’ll provide a strategy for calculating your feeds and speeds that uses the formulas for a starting guess and then modifies the numbers based on your specific operation and machine. What are speeds and feeds in CNC machining? What are the factors affecting speeds and feeds. Guide to calculating optimal feeds and speeds.

Here is the chart with the recommended cutting speed for different materials. 1. Materials: cutting speed for aluminum, brass, bronze, cast iron, magnesium, copper, stainless steel, carbon steel, titanium, etc. 2. Machining process: cutting speed for turning, drilling, reaming, and end milling. 3. Use Cutting Speeds And Feeds Calculator with simple shop formulas and access a full-featured, industry-leading calculator (free for a limited time). Thousands of top manufacturers rely on it daily. They trust the software because it saves them time and money.

The feeds and speeds chart is a systematic table that includes feed rate and cutting speed for different tooling, work materials, and machining operations. Engineers and CNC operators use this chart to find the best possible values to achieve efficiency, prolong tool life, and achieve accurate results for any specific CNC project.High Speed Machining: Tool Engagement Angle, Trochoidal Milling, Peeling, and all that Jazz. Dealing With Chatter When Milling: Fixing Chatter via Rigidity or Tuning Speeds and Feeds. Micro-Machining: How to avoid breaking those tiny little cutters. Advantages and Pitfalls of Rigid Tapping Long Reach Tools, Thin Walls, and Other Rigidity ChallengesDetermine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. 6061-T6, 5000, 6000, and 7000 series.FSWizard is the first and only online speed and feed calculator to consider dozens of variables when calculating Milling, Drilling and Turning Speeds and Feeds. Speeds and Feeds all kinds of Machining operations. Supports Milling, Drilling, Tapping, and Turning tools. Calculate Cutting Speed (SFM), Chip-Load (ipt), RPM, and Feed-Rate.

machining speeds and feeds chart

custom metal fabrications waterbury ct

Say hello to our patent pending, leakproof and plastic-free water bottle, Glacier. Designed with a flip-up silicone straw, and insulated stainless steel body, the Glacier will keep you hydrated without the plastic! These are great, no plastic, no leaks. Easy for toddlers to open and drink from.

cnc cutting speed and feed list for machining|cnc cutting speed formula