manufacturing drawings cnc machining In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best . Paper or board in which dye has been added into the beaker producing a sheet with consistent color throughout its thickness. The unfinished cardboard base or lid of the box still flat. Made from recycled paper products and virgin Kraft. Material is ground and combined with other materials in a beater to form pulp.

0 · technical drawings for cnc engineering

1 · technical drawing for cnc parts

2 · engineering drawing for cnc manufacturing

3 · drawing for cnc machinery

4 · cnc machining drawings

5 · cnc machining drawing template

6 · cnc drawings

7 · cnc drawing process

The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of .

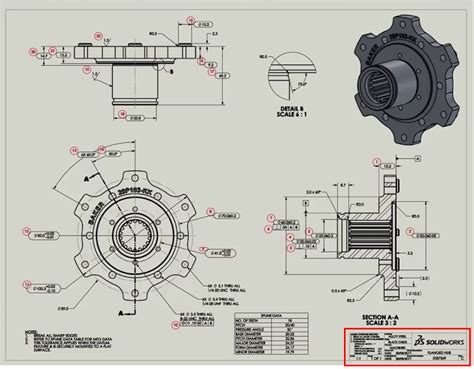

This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts .In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best . CNC machining drawings are essential for precision manufacturing, bridging the gap between design and product. They guide the machining process with detailed specifications, utilizing CAD software for . Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and .

Technical drawings are widely used in manufacturing to improve the communication of technical requirements between the designer and engineer and the manufacturer. To request a quote for custom CNC parts on the V1 .

In this article, I will provide an overview of technical drawings for CNC machining and examine their importance in the manufacturing process. I will also explain what is technical drawing, why you need it, and how to create this . A technical drawing for CNC Machining is an essential part to build a 3d part by CNC machining. It provides a detailed representation of the part or product that needs to be machined, allowing manufacturers to accurately .The Human Element. Even in this age of automation, the human element is invaluable. Manufacturing engineers must be proficient in interpreting manufacturing drawings. Their .

The ultimate purpose of a 2D technical drawing is to provide machinists and engineers with all the necessary information and clear instructions to ensure that the final product meets the intended specifications.

The Basics of 2D Drawings for CNC Machining. 2D drawings, also known as blueprints, provide a comprehensive plan for the final product. They incorporate all the necessary information, such as dimensions, tolerances, .Manufacturing Drawings – The Heart of CNC Machining . Manufacturing drawings are the language of production, communicating crucial details about a part's dimensions, material specifications, manufacturing process, and surface finishes. Without these, the sophisticated CNC machines would be clueless about what they need to create or how they .Creating a technical drawing for CNC machining is an essential part of the process, as it ensures that the part will be produced accurately and precisely. By following the steps outlined in this guide, you will be able to create a detailed and accurate technical drawing for CNC machining. CNC milling is a machining process in which custom-designed products or custom CNC parts are produced by using a rotating cutting tool and computerized controls. . Engineering drawings are important in the manufacturing industry, although it is not essential to request a quote. It helps decrease costs and improve communication between workers .

Introduction . Drawing for CNC machines is an essential skill for anyone involved in computer numerical control (CNC) machining. Whether you are a beginner or an experienced professional, it is important to have a solid understanding of how to produce accurate and efficient drawings that can be executed by CNC machines.So, how do you prepare a perfect technical drawing for manufacturing? We’ve listed 9 main steps below. 9 steps to prepare a perfect 2D technical drawing. Before we begin, select your template. Standard ASTM, DIN, and ISO templates are available. You can also create a custom template, but ensure that it includes all the necessary details. 1. A CNC machining drawing is a technical illustration that outlines the specifications, dimensions, and details necessary for manufacturing a part using Computer Numerical Control (CNC) machines. These drawings serve as a blueprint, guiding machinists throughout the machining process. Check out our full list of machining blueprint symbols to help you figure out what it is and what it does. . Home; CNC Programming; Blueprint Reading; Measuring & Quality Control; Machine Shop Math; About; Menu. Home; CNC Programming; Blueprint Reading; Measuring & Quality Control; Machine Shop Math; About; Complete Guide to Machining .

Ever since the dawn of computer numerical control (CNC) technology, the manufacturing industry has seen a tremendous surge in productivity and precision. At the heart of this machinery are intricate 3D drawings or models, which serve as the blueprint for creating complex and accurate parts. . Tips for Interpreting 3D Drawings in CNC Machining .

technical drawings for cnc engineering

technical drawing for cnc parts

Thanks for the clarification. I was imagining the former, the 2D drawing, with the manufacturing information. I worked as a CNC machine operator and always from those 2D prints. I always thought that the engineers provided the company with those drawings directly, and then the lead machinists would use BobCAD-CAM to write the CNC code.

In today's CNC machining environment, the manufacturing process usually begins with a 3D CAD model generated by specialized software. With the help of CAM software, the 3D model is translated into G-code, which is a CNC machine language. Once programmed, the CNC machine produces the part using subtractive methods.

Somewhere in the recent past, I trained a aircraft Part shop in Sprngfield, OH, in CNC lathe and mill Programming and I made sure to have everyone involved in the total manufacturing process in my class Designer, Draftsman, Supervisor of machining and programmer. The more they all understand, the smoother the manufacturing process. Short .

CNC Machining . Swagelok or Equal Drawings or Dimensions . The Swagelok drawings indicate the angle on the fitting does not match the ferrule, it is a steeper angle, which would make sense as the ferrule needs to have the front edge bite into the tube for grip and sealing - if the angles were the same, the whole ferrule would have to collapse .

ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers.In the world of engineering, a 2D drawing or engineering drawing is a type of technical drawing that conveys information about a part, such as its geometry, dimensions, and acceptable tolerance. Unlike a digital CAD file, which . The drawing is typically created using Computer-Aided Design (CAD) software and serves as a guide for the CNC machine to follow during the manufacturing process. The accuracy and completeness of the technical CNC . Computer numerical control (CNC) machining is a manufacturing process. It relies on code to control the movement of tools, such as lathes, router bits, and milling bits, . You must create a 2D drawing or 3D model and .

4. Scaling Up: The CNC Machining Process for Mass Production. Once the prototype is approved, we proceed to mass production. CNC Machining excels in maintaining high precision and repeatability, making it ideal for large-volume production. Here’s how Formal ensures seamless scalability:. Batch Production: We split the production into manageable .In CNC machining, 3D CAD drawings are used to program the CNC machine to create a physical object. The 3D model is imported into the CNC machine software, and the machine uses the information to guide the cutting tools and create the physical object. . CAD modeling is used in CNC machining and manufacturing to create digital designs of parts .

In CNC precision manufacturing, mechanical drawings are the basis for technicians to process and manufacture machined parts.A drawing is handed over by the mechanical design engineers to the production department. The designer expresses the requirements in the drawing of a CNC Machined part, and the production department carries out the manufacturing and inspection .Minimum of 5 years of experience in CNC machining operations, preferably in a manufacturing environment. Proficiency in reading and interpreting blueprints, CAD drawings, and GD&T specifications. Strong knowledge of CNC programming and the use of CAM software, such as Mastercam or Siemens NX.My student group is going to be sending out drawings to machine shops for manufacturing shortly. The parts have large pockets which have a lot of other features internal to them. The parts will have to be CNC milled, because of their complexity. . Protolabs CNC machining is a pretty competitive service for this kind of one-off. They have a .

Critical Steps in the Manufacturing Process Based on Technical Drawings. The manufacturing process consists of several phases, from the initial design phase to the final inspection of the finished product. . A CNC machine drawing is a technical drawing that provides detailed information about the specifications and dimensions of a part that . Fusion 360 is a cloud-based 3D CAD software with 2D drawing mode that integrates with CNC machining and other design and manufacturing processes. It requires a subscription and has a low price tag. In this guide, we give a brief overview of engineering drawing for CNC machining, everything you should know about engineering drawing. [email protected] +86 769 8289 0830; Design. Calculator . Junying Metal Manufacturing has developed high-level manufacturing technique in production fields of machining. .

With computer-aided design (CAD) conceptualizing intricate drawings and computer-aided manufacturing (CAM) translating them into CNC-executable code.Automation is the heartbeat of CNC machining, orchestrating a seamless transition from design concepts to tangible creations. . In the dynamic landscape of manufacturing, CNC machining emerges as .Our company takes care of the complete manufacturing process: you just need to send us your drawings and you will receive fully finished parts right on time. Leave a request. Straight to the point . B&K Precision Machining has established itself as a trusted leader in CNC machining and manufacturing. Our extensive knowledge and expertise span .

engineering drawing for cnc manufacturing

drawing for cnc machinery

Box roof vents (also called static, turtle, and louver vents) look like little boxes sitting on your roof. They allow air to escape as heat in your attic rises and pushes the hot air through the vents.

manufacturing drawings cnc machining|cnc machining drawings