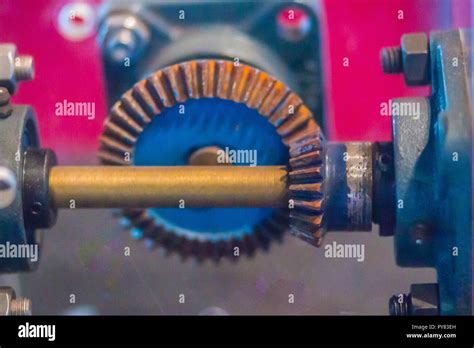

cnc bevel gear machine CNC machine with 6 axes for gear cutting of ring gears and pinions in one or more setups; Operator guidance in dialog via Windows; Programmable loading position; Easy ergonomic loading; Especially suitable for medium and large . Starfield USB/SD holder. Discover 3D models for 3D printing related to Usb Holder. Download your favorite STL files and make them with your 3D printer. Have a good time!

0 · things that use bevel gears

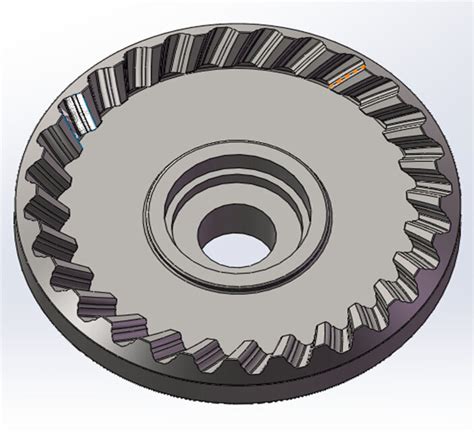

1 · internal bevel gear

2 · helical bevel gear

3 · disadvantages of bevel gears

4 · diagram of bevel gear

5 · bevel gears advantages and disadvantages

6 · bevel gear types

7 · bevel gear cutting methods

CNC Exchange has a 30,000-sq. ft. showroom. When you’re ready to buy a used CNC machine, view our on-site inventory and arrange to inspect a machine under power.

things that use bevel gears

Thanks to its outstanding grinding performance and universal design, this CNC-controlled bevel gear grinding machine from the G model series is an extremely economical concept for high .The C 60 bevel gear cutting machine covers the upper application range of the C .

do i need an electrical box for lights

For these applications, the Klingelnberg Zyklo-Palloid® tool system provides .CNC machine with 6 axes for gear cutting of ring gears and pinions in one or more setups; Operator guidance in dialog via Windows; Programmable loading position; Easy ergonomic loading; Especially suitable for medium and large .For face hobbing and face milling on the latest CNC machines at optimum speeds and feeds. The ideal solution for today’s medium to high volume face hobbing and face milling applications. .

The C 60 bevel gear cutting machine covers the upper application range of the C series. It is used for cutting bevel gearboxes for heavy-duty trucks and tractors, and has the same well-tried .For these applications, the Klingelnberg Zyklo-Palloid® tool system provides individual solutions with AMK blades made from HSS or holders equipped with carbide cutting plates for soft cutting and BN-equipped HPG-S clamping .

Manufacturers of straight bevel gears were relying on remanufactured mechanical machines, some of which are equipped with partial CNC functions like cradle roll, sliding base, ratio of roll, and indexing.The Hera 90 CNC gear hobbing machine combines advanced technology, precision components, and economic pricing to enable profitable production of high-quality spur gears, helical gears, straight bevel gears, and other hobbed . This leading combination of technology offers new opportunities for gear manufacturers to be more profitable. The Hera 30 offers 8 CNC axes, 1 module (25 DP) pitch rating, 40 mm (1.575 in) maximum workpiece diameter, .

Straight and spiral bevel gear manufacturing on 5-axis CNC machines using face mill cutters provides essentially the same throughput as conventional gear cutting machines—with these .C-B Gear has recently enhanced its spiral bevel gear manufacturing process by implementing CNC technology. This advancement allows us to produce both spiral and straight bevel gears .Thanks to its outstanding grinding performance and universal design, this CNC-controlled bevel gear grinding machine from the G model series is an extremely economical concept for high-precision final machining of the curved-toothed bevel gears of .CNC machine with 6 axes for gear cutting of ring gears and pinions in one or more setups; Operator guidance in dialog via Windows; Programmable loading position; Easy ergonomic loading; Especially suitable for medium and large series production of spiral bevel gears and hypoid gears for the automotive and commercial vehicle industry

For face hobbing and face milling on the latest CNC machines at optimum speeds and feeds. The ideal solution for today’s medium to high volume face hobbing and face milling applications. For significantly reduced blade blank sizes with specially developed and patented radial spacers for highest productivity and economics.The C 60 bevel gear cutting machine covers the upper application range of the C series. It is used for cutting bevel gearboxes for heavy-duty trucks and tractors, and has the same well-tried design as every C machine. In the C 60, special emphasis was placed on high static and dynamic rigidity.For these applications, the Klingelnberg Zyklo-Palloid® tool system provides individual solutions with AMK blades made from HSS or holders equipped with carbide cutting plates for soft cutting and BN-equipped HPG-S clamping blades for hard finishing. Manufacturers of straight bevel gears were relying on remanufactured mechanical machines, some of which are equipped with partial CNC functions like cradle roll, sliding base, ratio of roll, and indexing.

The Hera 90 CNC gear hobbing machine combines advanced technology, precision components, and economic pricing to enable profitable production of high-quality spur gears, helical gears, straight bevel gears, and other hobbed profiles. This leading combination of technology offers new opportunities for gear manufacturers to be more profitable. The Hera 30 offers 8 CNC axes, 1 module (25 DP) pitch rating, 40 mm (1.575 in) maximum workpiece diameter, and 10,000 rpm maximum hob speed.Straight and spiral bevel gear manufacturing on 5-axis CNC machines using face mill cutters provides essentially the same throughput as conventional gear cutting machines—with these added benefits: • Machine setup time is near zero, as opposed to mechanical machines • Different gear types can be cut on the same CNC machine

C-B Gear has recently enhanced its spiral bevel gear manufacturing process by implementing CNC technology. This advancement allows us to produce both spiral and straight bevel gears to AGMA 12 standards, including Klingelnberg specifications.Thanks to its outstanding grinding performance and universal design, this CNC-controlled bevel gear grinding machine from the G model series is an extremely economical concept for high-precision final machining of the curved-toothed bevel gears of .CNC machine with 6 axes for gear cutting of ring gears and pinions in one or more setups; Operator guidance in dialog via Windows; Programmable loading position; Easy ergonomic loading; Especially suitable for medium and large series production of spiral bevel gears and hypoid gears for the automotive and commercial vehicle industryFor face hobbing and face milling on the latest CNC machines at optimum speeds and feeds. The ideal solution for today’s medium to high volume face hobbing and face milling applications. For significantly reduced blade blank sizes with specially developed and patented radial spacers for highest productivity and economics.

The C 60 bevel gear cutting machine covers the upper application range of the C series. It is used for cutting bevel gearboxes for heavy-duty trucks and tractors, and has the same well-tried design as every C machine. In the C 60, special emphasis was placed on high static and dynamic rigidity.For these applications, the Klingelnberg Zyklo-Palloid® tool system provides individual solutions with AMK blades made from HSS or holders equipped with carbide cutting plates for soft cutting and BN-equipped HPG-S clamping blades for hard finishing. Manufacturers of straight bevel gears were relying on remanufactured mechanical machines, some of which are equipped with partial CNC functions like cradle roll, sliding base, ratio of roll, and indexing.The Hera 90 CNC gear hobbing machine combines advanced technology, precision components, and economic pricing to enable profitable production of high-quality spur gears, helical gears, straight bevel gears, and other hobbed profiles.

This leading combination of technology offers new opportunities for gear manufacturers to be more profitable. The Hera 30 offers 8 CNC axes, 1 module (25 DP) pitch rating, 40 mm (1.575 in) maximum workpiece diameter, and 10,000 rpm maximum hob speed.Straight and spiral bevel gear manufacturing on 5-axis CNC machines using face mill cutters provides essentially the same throughput as conventional gear cutting machines—with these added benefits: • Machine setup time is near zero, as opposed to mechanical machines • Different gear types can be cut on the same CNC machine

internal bevel gear

helical bevel gear

do i need to ground a junction box

disadvantages of bevel gears

(Washington, D.C., July 29, 2020) – U.S. Secretary of Agriculture Sonny Perdue announced today that the U.S. Department of Agriculture’s (USDA) Farmers to Families Food Box Program has distributed over 50 million food boxes in support of American farmers and families affected by the COVID-19 pandemic.

cnc bevel gear machine|helical bevel gear