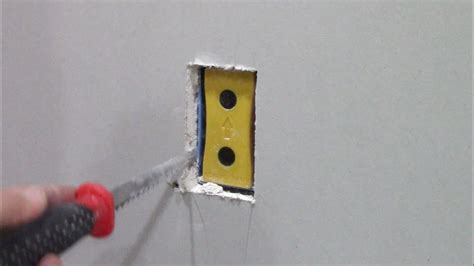

hanging drywall on ceiling and cutting out electrical boxes Make sure all electrical boxes are flush with the drywall surface before cutting holes. Follow these tips and pay close attention to detail to create a solid foundation for the taping and finishing, which will result in smooth, professional .

Since 1982 QST has been providing custom stamping parts for OEMs in a range of industries. We can manufacture metal stampings up to .25” thick and achieve tight dimensional tolerances of +/-0.0010”. Your parts will be delivered on time and production .

0 · how to mark electrical boxes

1 · how to mark drywall boxes

2 · how to cut holes in drywall

3 · hanging drywall for boxes

4 · easy way to cut drywall

5 · drywall hanging box markings

6 · cutting holes in electrical box

7 · cutting holes in drywall lights

At Cardinal MetalWorks, we offer a full range of services to meet your custom metal fabrication needs. We can produce exact sheet metal parts, use robots for welding, and provide top-notch finishing services.

This Old House general contractor Tom Silva shares some tricks-of-the-trade for accurately marking drywall cutouts. (See below for a shopping list and tools.. I wanted to show you a easy way to mark electrical boxes without havi. While on a project where the patio ceiling had been blown out during Hurricane Matthew. Here we’ll show you how to cut electrical box openings in drywall that fit perfectly the first time—without broken corners and especially without being too big. Oversized holes are a hassle to fix and look tacky with those big . Cutting out drywall to fit an electric box in the wall can be messy work if you don't do it right, potentially damaging the wall. Here's a tip to do it well.

In this video I show you a few different ways how to cut out electrical boxes in drywall.How to Hang Drywall By Yourself - https://youtu.be/f_70XO2iY_UBathro.Make sure all electrical boxes are flush with the drywall surface before cutting holes. Follow these tips and pay close attention to detail to create a solid foundation for the taping and finishing, which will result in smooth, professional .

Gaps around boxes are normal when hanging drywall. The standard tool for a beginner is a keyhole saw and careful measuring. Realize when measuring that drywall will likely have up to a 1/4" gap with whatever it's adjacent to, so pad .

4. Cutting Openings for Fixtures. Locating Fixtures: Reference your ceiling map to locate any lights, vents, or other fixtures that need openings.Measure from the walls to each fixture and .Inspect the ceiling joists for any damage and address that before hanging any drywall. Make sure all electrical boxes for lights or vents are tightly fastened, and remove any obstacles that might get in the way of the drywall installation. Amazon now sells it → http://amzn.to/2f26zDH Serious drywallers would likely never use it but weekend carpenters may like it. It uses high-powered magnets.. The outline for the box should be centered in the rectangle and on one end of it. Cut out the rectangle carefully with a drywall saw and clean the edges of the hole and the cut-out piece of drywall by scraping them with a .

Lifting a sheet of drywall up and down to perfect an electrical outlet opening is NOT an option. Clearly, measuring is NOT the way to go. Applying lipstick around the outside facing edge of a box is the perfect way to mark the . First things first, shut off the power to make sure that any wires inside the box are not energized. Then take a horizontal measurement from a known reference point, like the edge of the wall, to the center of the electrical box. Next, repeat the same process, starting your measuring tape at the top of the finished floor or at the bottom of the ceiling (whichever is .Calculated Industries 8105 Blind Mark Drywall Electrical Box Locator Tool – Powerful Rare-Earth Magnetic Targets (3) and Locator Kit . Cut out your Outlet Boxes like a PRO with MULTI-MARK! FrontLineTrainer . Videos for this product. 0:57 . Click to play video. . and cut the holes for the electrical boxes--but, . Speaking of sawzalls, I had a new guy the other day grab a super sawzall to trim some subfloor hanging out in the way of our new deck ledger. The kid stuffed the entire 10" blade inside the wall and in about 5 seconds (of course right when I wasn't watching) he cut through a water supply, a 2" drain and the bath electrical.

Personal preference. In the past, I've nailed up the boxes and then tried to cut the holes by measuring from the sides several times and then cutting out the holes before putting up the board over the boxes. That never seems to come out in the exact right spot that I don't have a gap around the box. Lastly, I've installed the boxes and then .

Yep, in construction these guys usually use 12' sheets on a ceiling which bow and flex easily. They tack the rock anywhere it hits wood. You start your rotozip in the center of the light and move outwards, you can hear it hit the edge of the light, drop the rotozip down to move outside the lip and zip around the hole.Would I be able to cut a hole for the new location and install an old work plastic ceiling box with the 3 tabs and hang my light fixture with that? There would be no stud to attach to, just the support of the drywall. The fixture is 4.5lbs. It’s in a soffit area above our sink and would be a ceiling mount, not a wall mount. Thanks!BTW, there's also the other solution for folks who can't measure: Insert the screws into the box's mounting holes so they protrude just slightly, lift drywall into place, press firmly so screws mark the back of the drywall, lower drywall, use those marks to align a spare box, draw a line around it and cut the opening. –A smart, simple and reusable drywall and painting tools. SIMPLE AND EASY TO USE - Use the Mark N Guard to cover the outlet. As you lay the drywall, the pointed tip of the Mark N Guard penetrates through the sheet and automatically shows you the center of the electrical box where you can cut around it.

Hopefully this will help you dyi peeps out there. It helped me 100%. I’m sure there are other ways, but this is how I did it A drywall saw is used to make cuts for windows and doors while a smaller keyhole saw is perfect for cutting around electrical boxes and other small openings. Make the cuts from the front side when possible to keep from roughing up the paper on the face.Cut Holes for Any Fixtures. After the drywall is installed, you can cut out the holes for light fixtures and vents. A spiral cutting tool or drywall saw is best for this work. Locate the marked points for fixtures on the installed drywall. Carefully plunge the cutting tool into the drywall at . Purchase the rotozip on Amazon http://amzn.to/2A8JAQ3Purchase drywall zip bits - http://amzn.to/2iSxRLDFor more home improvement tips visit .

Remodeling my bedroom and hanging all new drywall vs attempting to patch and fix the 70s era veneer paneling thats up now. . Also whats the easiest way to cut outlet boxes and switches out without too much work? I saw they make the magnet kit to go around and find them exactly. . Forgot to add the ceiling is currently drywall with a plaster . Most drywall cutting is done with the “score-and-snap” method, using a utility knife for the scoring, but a drywall utility saw is necessary for making cuts where you need to notch the material or make more than one cut .

I replaced a couple ceiling fans in my old house that did not have a box at all. I positioned the the low-profile support pan I was using where I wanted the hole in the drywall ceiling to go (centered on a joist), then cut the circle out with a jab saw that uses sawzall blades.

It can be routed next to the plate as long as the fan ceiling canopy fitting will cover it. Or cut a hole in the plate if need be. Install the box and cut the conduit to length at the resin plate. Install the protective bushing. Install the fan on the resin plate. Push the fan wires through the conduit at the resin plate and into the box and .

Octagon boxes come in different depths too, @robl45. Be aware, though, that replacing the box in the ceiling (especially if the box there is a new work box that's nailed into a ceiling rafter) isn't a 15-minute task, and will likely require removal of some drywall from the ceiling with subsequent patching and attempting to match the ceiling .

The main reason is that I use a drywall ceiling lift to place the panels and hold them in place as I cut out for electrical boxes or other openings and as I install drywall screws. This same lift can be used to hang the upper panels on walls as well but it is quite cumbersome and time consuming to accomplish. Then, position the sheet of wallboard in place, and push it firmly up against the outlet box. This transfers the lipstick to the drywall, leaving an outline of the box on the back of the sheet. Using a drywall keyhole saw, cut around the outside of the line. Finally, slide the sheet .

For the vertical seam, this is indeed common.To prevent crumbling at the edge, you can install the drywall then cut out the box hole. Place the drywall against the studs, apply screws without tightening them and use a utility knife in stead .

how many jobs are available in metal fabrications in usa

Cutting out electrical boxes and can lights when hanging drywall can be tricky work. Aside from upsetting the electrician by accidentally nicking his or her wires or chewing up the electrical box with the rotary tool, there’s the potential of making more work for yourself by cutting out the box in the wrong location when using a drywall saw. It can be used for practically all electrical boxes: metal, plastic, composite, rectangle, round, octagon, multi-gang, single-gang, standard, or thin. Just insert the target in the receptacle before hanging drywall. When you're ready to cut the hole, hold the Multi Mark Locator magnet over the area where you think the receptacle is located. Perfect cutouts for electrical boxes is important. Cutting out after the drywall is attached is the key. Also using a drywall router makes the job easier.When you are hanging Sheetrock on a ceiling, you will most likely run into an electric box meant for the lighting in that room. These are the “tricky” cuts when it comes to drywall because you will have to measure it from the ceiling, figure out how you’re going to place the drywall up, make the cut on the floor, then hope you got it all .

how to mark electrical boxes

how to mark drywall boxes

Look through the wide range of wholesale high demand machining cnc parts listings on Alibaba.com to find the right provider for your machining needs. All kinds of machining services are covered here.

hanging drywall on ceiling and cutting out electrical boxes|cutting holes in drywall lights