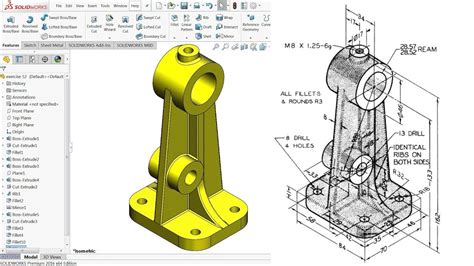

blueprint reading fundamentals for cnc machines Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining . generator sets are supplied with factory installed enclosures. Enclosures are constructed in a variety of styles and materials dependent on the manufacturer, type of ins. llation site, and ambient conditions likely to be encountered. This Information Sheet takes a .

0 · engineering blueprints for beginners

1 · cnc blueprints explained

2 · cnc blueprints examples

3 · cnc blueprint keys

4 · blueprints for cnc machining

5 · blueprint reading for cnc

6 · basic dimensions blueprint reading

7 · basic blueprint reading pdf

Becoming a sheet metal worker typically involves completing a combination of education and hands-on training, as well as obtaining industry certification. Here are the steps to become a sheet metal worker: High school education: Most sheet metal workers have at least a high school diploma or equivalent.

Start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples.CNC Programming; Blueprint Reading; Measuring & Quality Control; Machine .Check out our complete guide to GD&T symbols with tips to help you read and .Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining .

Regardless of the reasons, modern machinists still need to master how to read physical blueprints. To help, we’ve broken the process down into five easy steps. Start with the key! Reading blueprints isn’t meant to require some .Blueprint Reading Fundamentals Specification and Callouts for Machine Processes 1. Drills and Reamers 2. Counterbore, Spotface, and Countersink 3. Broach 4. Surface TextureCheck out our complete guide to GD&T symbols with tips to help you read and understand your manufacturing blueprints. Find out how to use datums and where they fit into your measurement. Learn how to work with basic dimensions in .

Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time . Learn the basics of blueprint reading including dimensions, zero points, and moreThis course is designed as an introduction to understanding blueprints in manufacturing and being able to visualize and understand the intent of the designer.

engineering blueprints for beginners

In this blog post, we’ll explain how to read blueprints for CNC machines and understand blueprints are critical for efficient production. In manufacturing processes, blueprints provide an invaluable resource for . Start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples.Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining operations, including drilling, milling, turning, and threading, and discuss how they are .

Blueprints are tools that communicate what needs to be built or made, what materials are needed and what specifications are required. They insure that a design is made with complete accuracy what meets the needs of the customer. Regardless of the reasons, modern machinists still need to master how to read physical blueprints. To help, we’ve broken the process down into five easy steps. Start with the key! Reading blueprints isn’t meant to require some obscure ritual or a complicated set of mathematical calculations.

junction box supplier in singapore

Blueprint Reading Fundamentals Specification and Callouts for Machine Processes 1. Drills and Reamers 2. Counterbore, Spotface, and Countersink 3. Broach 4. Surface TextureCheck out our complete guide to GD&T symbols with tips to help you read and understand your manufacturing blueprints. Find out how to use datums and where they fit into your measurement. Learn how to work with basic dimensions in our guide. Includes all symbols per ASME Y14.5 and info on lesser-known legacy blueprint symbols. Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time meeting the part requirements. The first thing to look at is the job description box. Learn the basics of blueprint reading including dimensions, zero points, and more

This course is designed as an introduction to understanding blueprints in manufacturing and being able to visualize and understand the intent of the designer. In this blog post, we’ll explain how to read blueprints for CNC machines and understand blueprints are critical for efficient production. In manufacturing processes, blueprints provide an invaluable resource for engineers who need to . Start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples.

Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining operations, including drilling, milling, turning, and threading, and discuss how they are .

Blueprints are tools that communicate what needs to be built or made, what materials are needed and what specifications are required. They insure that a design is made with complete accuracy what meets the needs of the customer. Regardless of the reasons, modern machinists still need to master how to read physical blueprints. To help, we’ve broken the process down into five easy steps. Start with the key! Reading blueprints isn’t meant to require some obscure ritual or a complicated set of mathematical calculations.Blueprint Reading Fundamentals Specification and Callouts for Machine Processes 1. Drills and Reamers 2. Counterbore, Spotface, and Countersink 3. Broach 4. Surface TextureCheck out our complete guide to GD&T symbols with tips to help you read and understand your manufacturing blueprints. Find out how to use datums and where they fit into your measurement. Learn how to work with basic dimensions in our guide. Includes all symbols per ASME Y14.5 and info on lesser-known legacy blueprint symbols.

Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time meeting the part requirements. The first thing to look at is the job description box. Learn the basics of blueprint reading including dimensions, zero points, and more

This course is designed as an introduction to understanding blueprints in manufacturing and being able to visualize and understand the intent of the designer.

cnc blueprints explained

junction box sign

junction box street

What gauge sheet metal is used for auto body repair? Typically, 18-gauge sheet metal is used for body panels, with mild steel being the preferred material. Racers may opt for 20-gauge sheet metal over 18-gauge for lighter mechanisms.

blueprint reading fundamentals for cnc machines|engineering blueprints for beginners