caulking process in sheet metal Sealing the bottom of a metal building is a crucial step in its construction and maintenance, protecting it from moisture, pests, and weather elements. This process involves the use of . The UNIVIEW TR-JB03-H-IN-SE Junction Box with Lid is a robust and reliable mounting accessory crafted for seamless integration with a variety of camera types. Its premium aluminum alloy construction and thoughtful design make it the ideal solution for organizing and protecting camera installations.national fabricator of EQUITONE fiber cement, Trespa phenolic resin and ALPOLIC metal composite panel systems for architectural aesthetics fascia / facade design elements.

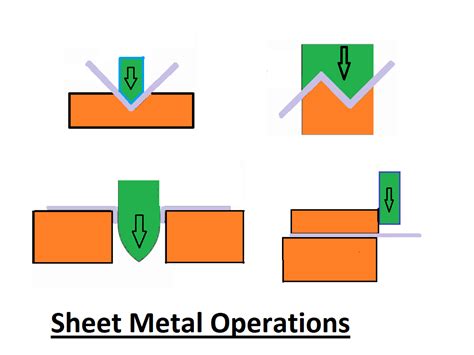

0 · slotting operation in sheet metal

1 · shearing operation in sheet metal

2 · parting operation in sheet metal

3 · embossing operation in sheet metal

4 · caulking for concrete to metal

5 · best exterior caulking for metal

6 · best caulking for metal building

7 · best caulk for galvanized metal

We have grown to be a respected mainstay of the metal fabrication industry in Hawaii through the development and investment in people and machinery capable of performing custom metal requirements of all types and sizes.

In this video, Danny, from Horizon Roofing, Inc., will show you how to properly apply caulk on sheet metal coping and cover plates. Caulking is an important .Sealing the bottom of a metal building is a crucial step in its construction and maintenance, protecting it from moisture, pests, and weather elements. This process involves the use of .PURPOSE:To stabilize a position of a sheet metal and its bending angle and stabilize caulking strength and spring pressure by allowing a projecting part provided on a pedestal to pass .Waterproof sealant for metal adheres upon contact with metal surfaces, closing the gap on seams, joints, and around fasteners. SMP (silane-modified polymers) sealants, for instance, form a waterproof bond and can be applied on wet .

slotting operation in sheet metal

shearing operation in sheet metal

Begin by cleaning the area to be caulked thoroughly, removing any dirt, dust, grease, or old caulk residue. Use a putty knife or scraper to remove loose paint or debris from the joint. Next, ensure the surface is completely dry before .Properly applied caulking will seal joints and cracks from the intrusion of water, air, dust, insects, pollution and noise. Choosing the right caulk and correctly applying it will reduce failures by .

There are many methods of joining adjacent sections of sheet metal. The following information will focus on the most commonly used types of seams, and key points for installers to remember in .

In this video, Danny, from Horizon Roofing, Inc., will show you how to properly apply caulk on sheet metal coping and cover plates. Caulking is an important .

Caulks typically are associated with filling gaps that do not experience much expansion or contraction, and are used to prepare for painting. They are rigid and inflexible. In metal construction, caulks are used on the interior filling gaps between drywall, windows and trim, or casework before paint is applied.Sealing the bottom of a metal building is a crucial step in its construction and maintenance, protecting it from moisture, pests, and weather elements. This process involves the use of proper sealants, correct application techniques, and the right preparation of the surface.PURPOSE:To stabilize a position of a sheet metal and its bending angle and stabilize caulking strength and spring pressure by allowing a projecting part provided on a pedestal to pass through.

Waterproof sealant for metal adheres upon contact with metal surfaces, closing the gap on seams, joints, and around fasteners. SMP (silane-modified polymers) sealants, for instance, form a waterproof bond and can be applied on wet substrates.

Begin by cleaning the area to be caulked thoroughly, removing any dirt, dust, grease, or old caulk residue. Use a putty knife or scraper to remove loose paint or debris from the joint. Next, ensure the surface is completely dry before applying the caulk.Properly applied caulking will seal joints and cracks from the intrusion of water, air, dust, insects, pollution and noise. Choosing the right caulk and correctly applying it will reduce failures by keeping shrinkage and splitting to a minimum. Understanding the characteristics and limitations of caulk is vital to the caulking’s performance.There are many methods of joining adjacent sections of sheet metal. The following information will focus on the most commonly used types of seams, and key points for installers to remember in performing their work. 15.1. Overlaps. The simplest and most basic seam is the lap joint. Caulking is the process of applying a flexible sealant to gaps and cracks in various surfaces, such as walls, windows, doors, and trim. The sealant, called caulk, adheres to surfaces to create a watertight, airtight, and pest-proof barrier.

Caulking is the process of sealing gaps and joints between surfaces to prevent water, air, and debris infiltration. It forms a flexible and waterproof seal, protecting your home from damage and reducing energy costs. Learn how to master the art of caulking for a polished finish. In this video, Danny, from Horizon Roofing, Inc., will show you how to properly apply caulk on sheet metal coping and cover plates. Caulking is an important . Caulks typically are associated with filling gaps that do not experience much expansion or contraction, and are used to prepare for painting. They are rigid and inflexible. In metal construction, caulks are used on the interior filling gaps between drywall, windows and trim, or casework before paint is applied.

parting operation in sheet metal

Sealing the bottom of a metal building is a crucial step in its construction and maintenance, protecting it from moisture, pests, and weather elements. This process involves the use of proper sealants, correct application techniques, and the right preparation of the surface.

PURPOSE:To stabilize a position of a sheet metal and its bending angle and stabilize caulking strength and spring pressure by allowing a projecting part provided on a pedestal to pass through.Waterproof sealant for metal adheres upon contact with metal surfaces, closing the gap on seams, joints, and around fasteners. SMP (silane-modified polymers) sealants, for instance, form a waterproof bond and can be applied on wet substrates.

Begin by cleaning the area to be caulked thoroughly, removing any dirt, dust, grease, or old caulk residue. Use a putty knife or scraper to remove loose paint or debris from the joint. Next, ensure the surface is completely dry before applying the caulk.

Properly applied caulking will seal joints and cracks from the intrusion of water, air, dust, insects, pollution and noise. Choosing the right caulk and correctly applying it will reduce failures by keeping shrinkage and splitting to a minimum. Understanding the characteristics and limitations of caulk is vital to the caulking’s performance.There are many methods of joining adjacent sections of sheet metal. The following information will focus on the most commonly used types of seams, and key points for installers to remember in performing their work. 15.1. Overlaps. The simplest and most basic seam is the lap joint. Caulking is the process of applying a flexible sealant to gaps and cracks in various surfaces, such as walls, windows, doors, and trim. The sealant, called caulk, adheres to surfaces to create a watertight, airtight, and pest-proof barrier.

Our VT-J301 and VT-J302 junction boxes are designed for universal compatibility. They have the most common screw hole patterns used in the industry so they can be installed with almost all manufacturer makes and models of CCTV cameras and network IP cameras.

caulking process in sheet metal|best caulk for galvanized metal