sheet metal tig welding Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more This document provides assembly instructions for a WorkBee CNC machine kit. It begins by listing the contents of the kit and required tools. It then walks through assembling the drag chains, power supply, limit switches, CNC controller mount, and completing the wiring.

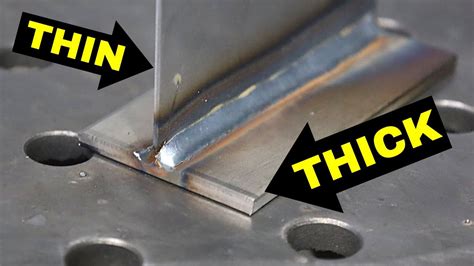

0 · welding thin to thick metal

1 · welding stainless steel sheet metal

2 · welding sheet metal without warping

3 · welding 14 gauge sheet metal

4 · tig welding stainless sheet metal

5 · tig welding automotive sheet metal

6 · mig welding galvanized sheet metal

7 · 18 gauge weldable sheet metal

75+ Years of metal processing solutions in Worcester, MA, U.S.A.! Worcester Manufacturing has continually evolved since 1938, starting out in downtown Worcester as Independent PlatIng. Beginning with just one employee, the company offered plating and specialty coating.31 were here. We specialize in custom builds , equipment repair , metal decor and anything in between. If it .

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See moreNow that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See moreWelding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these .

Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in. In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible.TIG (Tungsten Inert Gas) welding excels at joining thin sheet metal. It provides superior control, minimal distortion, and clean, strong welds. By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise . Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding.

MIG vs. TIG Welding: Key Differences. MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding are two popular welding methods, each with distinct advantages: Weld Speed: MIG welding is faster, ideal for . Auto body sheet metal is relatively thin, and this can present some challenges for welders particularly those who are accustomed to welding thicker materials. Welding nearly always causes some distortion: the metal in and . 8 TIG Welding. 8.1 Considerations for TIG welding; 9 Sheet Metal Part Design for Manufacturing Tip. 9.1 CORNERS AND WELDING; 10 Sheet Metal Fabrication Welding FAQ. 10.0.1 What are the key welding methods . TIG welding is preferred where practical because it is neater and cleaner than MIG welding, which introduces new material into the weld joint. . Butt-welding large sections of sheet metal can be facilitated with this rig, which uses clamps and wedges to force alignment of the two pieces to be joined. Heat Up, Cool Down, Repeat .

Sheet Metal TIG Welding Tips. 1 for 1 rule: The best way to estimate the heat input needed for welding is by applying the 1 for 1 rule. This means that 1 amp should be used per 1 thousandth (0.001) inch of thickness. This is especially useful for carbon steel. But when it comes to stainless steel or other nickel-based metals, less heat is needed. Sometimes, sheet metal welding welders may use separate filler metal in TIG welding to reinforce the seams. However, it is usually suitable for non-ferrous metals like aluminum, copper, titanium, etc., especially in the aerospace industries, among . The PRIMEWELD TIG 225X is a formidable welding machine for sheet metal work. Its dual TIG/Stick welding capability allows it to easily handle different welding tasks. The precise control over amperage, ranging from 10-225A, allows for very fine work on sheet metal, maintaining the integrity of the material.

1/16 filler on 1/16 sheet metal doesn't work well. The amount of heat required to melt the sheet is vasty different from the heat for both sheet and filler. 16 gauge sheet metal is much, much easier with .040 filler. The heat range is better. If you can't get some tig wire, you can uncoil a spool of .045 might wire.

welding thin to thick metal

I only have a harbor freight tig right now to play with. I am getting the Miller Syncrowave 200 sometime soon. I think I figured away to get a proper working pedal on the machine and should be starting it soon. Anyway while playing around on the tig I thought I would try and lay down a bead or two on 20 gauge sheet metal. I wish I had taken the pictures with a . On this episode of Make It Kustom I show you how to butt weld thin sheet metal body panels using tig welding. This is a fender repair on a customers Fox body.High-quality sheet metal welding services are provided by Dynamic Design & Manufacturing, with a focus on MIG and TIG welding. Give us a call right now to learn more! . (TIG) welding is an arc welding process that uses a non-consumable tungsten electrode to produce the weld.

Most often, TIG welding is used for thinner gauged sheet metals. TIG welding can operate at lower power levels, and can be a slower and more delicate process than MIG welding. Spot welding is also sometimes called resistance spot welding. The fusing of two metal surfaces by way of heat generated by resistance to an electric current.https://www.proshaper.comOur Amazon Storefront:https://www.amazon.com/shop/proshaperIn this video Wray shows the steel sheet metal butt welding results after. In general, though, TIG welding sheet metal can be done like TIG welding any other metal. Get your amps going, stick to a consistent travel speed and dab, dab, dab. If the fit-up is tight (and thin) enough, you don’t even need filler, but you should keep it on hand to add if needed. For example, if the weld was opening up and widening, you .Precision Machine Fabrication is your trusted sheet metal expert in Winston-Salem, NC. Get started on your custom project today! 919-231-8648 [email protected] Request a Quote. Home; About. Management Team; Our Fabrication Process; . Explore Our Sheet Metal Bending Services. MIG and TIG Welding.

Anybody have any advice on tig welding 18 gauge steel? I can seem to do 16 gauge alright way down at 9 amps but 18 gauge is just blow through from the moment I pull the trigger. . It's up to you to manipulate sheet . Sheet metal thickness suitable for welding typically ranges up to 1/4 inch using MIG or TIG welding, with TIG preferred for finer work on thinner metals. Which welding is best for thick metal? Stick welding or Flux-Cored Arc . Mastering welding techniques, like welding different thicknesses and types of metals, can take decades. Whether you’re a veteran welder or new to the field, take a look at these ten tips to improve TIG welding thin sheet metal. What Makes Welding Thin Metal Difficult? There are a lot of things that can go wrong when you’re welding. Successfully TIG welding sheet metal requires properly controlling heat and preventing warpage. Learn some techniques from fabricators Bodie Stroud and Josh .

After TIG welding galvanized sheet metal, post-welding processes are crucial for ensuring the durability and longevity of the weld. These processes include cleaning the weld area to remove any zinc residue, applying a zinc-rich primer to protect against corrosion, and heat treating to relieve any residual stresses in the metal. Cooling And CleaningTIG & MIG sheet metal welding. Metals including: mild steel (0.8-10mm), stainless steel (0.8-10mm), aluminium (0.8-10mm). EN1090-2 approved. . Sheet metal welding is a common manufacturing process whereby metals are fused together using extremely high temperatures. During cooling, the joints harden creating permanent structures.Tig Welding Get a Quote. CO2 Welding Get a Quote. Spot Welding Get a Quote. Sheet Metal Welding Materials. Aluminum. Iron. Titanium. Steel. Stainless steel. Bronze. . Sheet Metal Welding Tolerances and Standards Standards Geometric tolerance Linear tolerance Flatness CNC Milling 0.2 mm-0.5 mm. CNC Turning \ Position .

welding stainless steel sheet metal

Common Types of Sheet Metal Welding Process “How to weld sheet metal” is the most common question that follows. There are a variety of techniques and strategies for welding sheet metal, and each has its own set of applications in specific situations. Let’s have a look at the various sheet metal welding techniques. MIG Welding Thin materials, such as sheet metal or thin-walled tubing, present unique challenges when tig welding due to their thinness and sensitivity to heat. Welding thin materials require high precision and control to avoid warping or melting through the material. . Is Tig Welding Good For Thin Metal? TIG welding is a good choice for welding thin . At Avon Lake Sheet Metal Company, we offer MIG, TIG, and spot welding in addition to our fabrication services. We also provide CNC machining, 3D modeling, and design services.Visit us today at www.avonlakesheetmetal.com or call (440) 933-3505 to discover what we can do for you.Hello everyone.It is not easy to weld thin sheet metal with a general welding machine.Therefore, there are many cases of using a cold welding machine when we.

Welding sheet metal is a very critical process within the modern concept of manufacturing. The construction of metal structures, pipelines, and tanks is among the most common applications for sheet metal welding. . TIG, and stick welding, each offering unique advantages depending on the application.For instance, in a recent project involving .

welding sheet metal without warping

welding 14 gauge sheet metal

Worthington Enterprises (NYSE: WOR) is a market-leading acquirer, designer and manufacturer of innovative building products, consumer products and sustainable energy solutions. Worthington Steel (NYSE: WS) is a market-leading steel processor and producer of electrical steel laminations and automotive lightweighting.

sheet metal tig welding|mig welding galvanized sheet metal