what metal is sheet metal • "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See more Nemaco provides mobile & portable enclosures, with caster wheels for all types of NEMA enclosures cabinets and boxes for electrical equipment. We have added enclosures with roller wheels to our product catalog.

0 · what is sheet metalworking

1 · what is considered sheet metal

2 · types of sheet metal material

3 · sheet metal examples

4 · grades of sheet metal

5 · different types of metal sheets

6 · characteristics of sheet metal

7 · 20 gauge sheet metal lowe's

Ericson's extra depth double sided outlet box with duplex coverplates is molded of thermoplastic elastomer which makes it non-conductive, crush proof and resistant to jobsite oils. Shop more Ericson products at HomElectrical today!

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or . See moreHand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The . See moreBendingThe equation for estimating the maximum bending force is,$${\displaystyle F_{\text{max}}=k{\frac {TLt^{2}}{W}}}$$,where k is a factor taking into account several parameters . See more

Fasteners that are commonly used on sheet metal include: clecos, rivets, and sheet metal screws. See more

• "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See moreStainless steelGrade 304 is the most common of the three grades. It offers good corrosion resistance while . See more

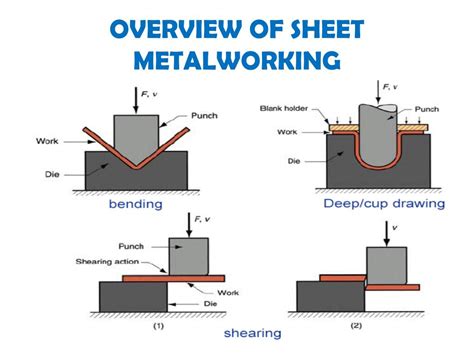

The use of sheet metal, through a comprehensive cold working process, including bending, shearing, punching, laser cutting, water jet cutting, riveting, splicing, etc. to make the final product we want (such as computer chassis, washing machine shells, . See more

• Circle grid analysis• Corrugated galvanised iron, also known as Corrugated Sheet Metal• Diamond plate• Forming limit diagram See moreSheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than .Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Countless everyday objects are fabricated from .

The various types of sheet metals include stainless steel, aluminum, brass, galvanised steel, cold-rolled steel, pre-plated steel, tool steel, carbon steel, and alloy steel. 1. Stainless Steel. the . Stainless Steel. Known for its exceptional resistance to rust and corrosion, stainless steel is often used in applications exposed to moisture or harsh chemicals. It’s a popular .When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the

Sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch through sheet metal. The force, usually made of hardened tool steel and pierces through the metal, removes the . In this video, you'll learn what sheet metal fabrication is and how it works. Sheet Metal fabrication is a manufacturing process where flat sheets of steel o.Sheet metal doors in a stone doorframe is the only situation where sheet metal ever makes sense. Well, that and emergency repairs where you happen to not have any stone and need to upgrade twigs or wood. Reply reply .

Advantages of the precision sheet metal jobs were indoors, you have your own bench and tools, no need to travel to job sites or climb up ladders etc. Plus its very hard to learn, and keeps out excess workers. Over time you learn to design and make all kinds of things like tools, dies, welding fixtures, jigs etc. On top of that when you learn . Probably, you are wondering whether sheet metal grinding is a primary or secondary operation in the metal fabrication process. Or, you would like to know how to grind sheet metal, choose effective grinding tools, improve efficiency, and get a perfect surface finish. Well, this guide is your go-to resource for grinding sheet metals.

Bending Bending is the most common process, where sheet metal is deformed along a straight axis to create angular or curved profiles. This can be done using machines like press brakes, which apply a precise amount of pressure to bend the metal without breaking it. Air bending, coining, and bottoming are popular bending methods used to achieve different . Uses for Galvalume® Metal Roofs & Walls. Overall, Galvalume is suitable as a roof, wall, trim, accent, and more in most building applications in some of the most extreme environments, including non-coastal hurricane zones, locations with high rain or snowfall, high-temperature regions, and more. Some common uses for Galvalume include: Eastwood’s 2-sided sheet metal gauge for mild steel includes gauge measurements on one side and nominal measurements on the other (click image for more) As a result, for each “gauge” there is a consistent weight for a given square inch or square foot of a given material, regardless of whose mill produces it. .What is the sheet metal fabrication process? The sheet metal fabrication process involves design, material selection, cutting, forming, joining, and finishing to create metal components and structures. Conclusion. Sheet metal fabrication is a fundamental process that has shaped the modern world in numerous ways. It is wide ranging, and we have .

Safety: Metal roofs are a safe option in areas prone to lightning strikes or wildfires as they won’t spark and ignite into flames. Aesthetics: Metal roofs have come a long way in recent decades– you have lots of choices when it comes to colors, finishes, styles, and more. A modern option that can look great on a home or building, metal . Sheet metal is a general category for metals that are approximately 0.018 to 0.250 in thickness. The thickness of sheet metal is often designated by a gauge rather than inches or millimeters. However, different types of material will have a slightly different gauge system to designate their thicknesses. Aluminum, steel, galvanized steel . Sheet metal is a thin layer of metal formed into sheets, and it comes in various types—steel, aluminum, copper, and more. Types of Sheet Metal Steel Sheet : Often used in construction and is generally magnetic.

need help manufacturing sheet metal? want to post your fabrication for all to updoot? come to r/sheetmetal to discuss all things sheet metal. Design, Fabrication, Installation. Welding, HVAC, Roofing, commercial kitchen stainless, home renovation, sheet metal art & etc. !Metal Sheets at Tractor Supply Co. Buy online, free in-store pickup. Shop today! . Hillman SteelWorks 12 in. x 24 in. #26 Solid Steel Sheet, Zinc-Plated. 0 (0) | Item # 352107199. Pickup Today. FREE. Same Day Delivery. Standard Delivery .99. Add to cart. Compare.Sheet metal fabrication is a multifaceted manufacturing process that involves the shaping, cutting, and assembling of metal sheets to create a wide range of custom components. This process is essential for numerous industries, .

Sheet Metal is arguably one of best component deals at outpost. If we give 100 metal the value of 7 scrap and 1 HQM the value of 6 scrap. The total recycled value of would be 21. Quite close to the outpost cost of 30. 2. Thesheet metal goes into an electrolyte (it is a solution). This solution contains dissolved metal ions of the plating material. 3. An electrical current passes through the solution. Thus, the sheet metal can be considered as the cathode or negative electrode, while the other metal plate will be the anode or positive electrode. 4.

Hydroforming: Hydroforming is a shaping process that uses hydraulic pressure to press the die upon the metal sheet. In this process, the metal sheet is pressed by the die to form the desired shape at room temperature. Hydroforming is often used for ductile materials. Roll Forming: In the roll forming process, a long metal sheet is passed .Sheet Metal fabrication is the creation of useful metallic parts and structures by the application of multiple fabrication processes. Various special tools are used in this process to convert sheet metals into useful components by minimal efforts. It is a value-added process to create machines, structures, or component parts following engineering drawings which usually serves as the . Sheet metal fabrication services are required for nearly all commercial and industrial products. Learn more about the steps and tools used in the sheet metal fabrication process and the types of sheet metals available. 360-652-4200 REQUEST A QUOTE. 360-652-4200 .Sheet metal fabrication transforms flat metal into functional, complex parts through a variety of cutting, forming, and joining techniques. From everyday household items to advanced aerospace components, this versatile process shapes the world around us. By understanding the basics of sheet metal fabrication, you can make informed decisions for .

A sheet metal mechanic is a professional who is skilled in molding sheet metal for use in construction or shipping projects. Sheet metal mechanic skills include altering, welding, repairing and assembling sheet metal products. Their duties are much the same as a sheet metal worker, but with additional responsibilities when it comes to .Prices average for metals in the United States and Canada. Current Scrap Metal Prices; Scrap Metal Scrap Price Updated Price Date; Copper National Average: .41/lb: . Old Sheet Aluminum: The metal sheet serves as a layer to protect ductwork, electrical outlets, plumb work, etc., from damage when you’re drilling. Once you detect the metal sheet, stop drilling to prevent damaging valuable installations. In this article, I’ll explain how to tell if a metal sheet is behind your drywall, even without a drill. You’ll also learn ..47/lb-12.28% Submit price: Painted Aluminum: Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere! Select Size; 1 x 2 Ft. 1 x 4 Ft. 1 x 8 Ft. 2 x 2 Ft. 2 x 4 Ft. 3 x 4 Ft. 4 x 4 Ft. ..42/lb: 116.00% Submit price: PC Board with Steel: Metals, such as steel, can be classified into many different categories based on their unique properties. They may vary in strength, durability, density, melting points, and composition, all of which are important when picking the best material for the job.However, one of the most essential ways to classify metals is whether they are ferrous or non-ferrous..35/lb: 0.00% Submit price: PC Boards: .60/lb .

what is sheet metalworking

what is considered sheet metal

types of sheet metal material

Two junction boxes are each located on different walls, 18'' from the same corner. Given a 90 ° bend with a take-up of 6 ° and a gain of 4", what is the developed length of the conduit .

what metal is sheet metal|20 gauge sheet metal lowe's