cnc machinable foam We use 1lb density foam (similar to Styrofoam used in shipping) to mill nests that aid the bonding and shipping of SLA, FDM, and SLS rapid prototypes. A secondary function of these nests is to verify the size of the 3D Printed parts.

forum. by Doug (Corpus Christi,TX) Jody: Thanks , I love the web site. You have a great way of conveying your ideas. I just bought a Everlast power tig 250 ex after watching your "show" I had the thing welding aluminum in no time,thanks to you.. I like the Nomad and I'm gonna git me one. Thanks again Doug -----

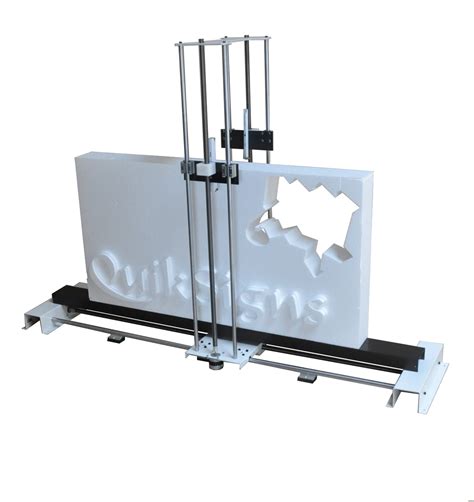

0 · hotwire direct foam cutting machine

1 · hobby cnc foam cutter

2 · cnc router for foam cutting

3 · cnc machine for eva foam

4 · cnc machine for cutting foam

5 · cnc foam cutting machine price

6 · best cnc foam cutter factories

7 · 5 axis cnc machine foam

Stamping Process in Sheet Metal. The stamping process in sheet metal involves several key steps to transform flat sheets into shaped components. It begins with designing the part and creating custom tooling, including dies tailored for precision and repeatability.

Mix and pour into molds to capture intricate detail when casting parts, linings, and prototypes. Line the walls of furnaces, freezers, ductwork, and buildings to keep heat in or out. Choose from .Choose from our selection of tooling foam, including prototyping foam, tool .Uniform, grain-free and highly machinable, LAST-A-FOAM ® tooling foam boards are ideal for master models, check fixtures, rapid prototypes, mold and .Mix and pour into molds to capture intricate detail when casting parts, linings, and prototypes. Line the walls of furnaces, freezers, ductwork, and buildings to keep heat in or out. Choose from our selection of machinable foam, including prototyping foam, foam casting compounds, and more. In stock and ready to ship.

Uniform, grain-free and highly machinable, LAST-A-FOAM ® tooling foam boards are ideal for master models, check fixtures, rapid prototypes, mold and foundry patterns, master-plugs, and composite tooling. Our rigid tooling foam boards bond securely and easily using a variety of adhesive systems. We use 1lb density foam (similar to Styrofoam used in shipping) to mill nests that aid the bonding and shipping of SLA, FDM, and SLS rapid prototypes. A secondary function of these nests is to verify the size of the 3D Printed parts.Our CNC-machining services deliver on all that – and more. Why waste money and time shipping foam sheet stock or buns – at full rate – to a third party to machine and re-ship them as parts to you? Let General Plastics produce, bond-to-size, and machine our foam to .High density urethane foam board also known as HDU board is used for hand-carved signs as well as CNC-machining. RAKU® TOOL Styling Board (SB) has a fine surface structure and lends itself to both manual and mechanical processing.

Choose from our selection of tooling foam, including prototyping foam, tool-organizing foam, and more. In stock and ready to ship.At American Micro Industries, we have specialized tools and project engineers that help us create custom foam machining solutions for our customers. We use the most advanced CNC milling methods to ensure all foam products are structurally sound and retain their thermal and mechanical properties.CORAFOAM® can be cut with anything that can cut wood, including CNC machines, standard woodworking tools, and waterjet cutters. Its closed cellular structure and absence of fibers or granular structure result in crisp, excellently defined edges after fabrication.Our Carving Foam Machining Capabilities. American Micro Industries can accommodate all your polyisocyanurate machining needs. We can perform custom CNC machining for our #2. #3, #4 and #6 rigid carving foam materials. We also offer both duna board and sign board machining.

With its excellent workability, grain-free consistency and broad range of densities (4 lb/ft 3 through 31 lb/ft 3), CORAFOAM® provides solutions to craftsmen and engineers alike.Mix and pour into molds to capture intricate detail when casting parts, linings, and prototypes. Line the walls of furnaces, freezers, ductwork, and buildings to keep heat in or out. Choose from our selection of machinable foam, including prototyping foam, foam casting compounds, and more. In stock and ready to ship.

Uniform, grain-free and highly machinable, LAST-A-FOAM ® tooling foam boards are ideal for master models, check fixtures, rapid prototypes, mold and foundry patterns, master-plugs, and composite tooling. Our rigid tooling foam boards bond securely and easily using a variety of adhesive systems. We use 1lb density foam (similar to Styrofoam used in shipping) to mill nests that aid the bonding and shipping of SLA, FDM, and SLS rapid prototypes. A secondary function of these nests is to verify the size of the 3D Printed parts.Our CNC-machining services deliver on all that – and more. Why waste money and time shipping foam sheet stock or buns – at full rate – to a third party to machine and re-ship them as parts to you? Let General Plastics produce, bond-to-size, and machine our foam to .High density urethane foam board also known as HDU board is used for hand-carved signs as well as CNC-machining. RAKU® TOOL Styling Board (SB) has a fine surface structure and lends itself to both manual and mechanical processing.

Choose from our selection of tooling foam, including prototyping foam, tool-organizing foam, and more. In stock and ready to ship.At American Micro Industries, we have specialized tools and project engineers that help us create custom foam machining solutions for our customers. We use the most advanced CNC milling methods to ensure all foam products are structurally sound and retain their thermal and mechanical properties.CORAFOAM® can be cut with anything that can cut wood, including CNC machines, standard woodworking tools, and waterjet cutters. Its closed cellular structure and absence of fibers or granular structure result in crisp, excellently defined edges after fabrication.

Our Carving Foam Machining Capabilities. American Micro Industries can accommodate all your polyisocyanurate machining needs. We can perform custom CNC machining for our #2. #3, #4 and #6 rigid carving foam materials. We also offer both duna board and sign board machining.

16 gauge sheet metal angle

hotwire direct foam cutting machine

hobby cnc foam cutter

cnc router for foam cutting

On sheet metal all you can do is stich weld. Otherwise, you will blow holes through the metal. Maybe, some experianced guys can pull off large beads.

cnc machinable foam|best cnc foam cutter factories