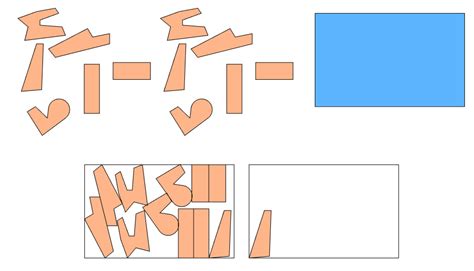

cnc how to nest part with toolpath How to use layers and toolpath templates to easily create toolpaths after nesting objects in multiple sheets. This lesson applies to Vectric VCarve Pro, Aspire, and Cut2D Pro but some aspects can be used in the desktop versions . No, you do not send yourself a 1099 for the amount of distributions you took from the S-Corp. The income you received from the S-Corp for the year is accounted through .

0 · nesting tool paths freecad

1 · nesting tool path template

2 · nesting paths for cnc template

3 · nesting paths for cnc free

4 · how to make toolpaths

$29.26

How to use layers and toolpath templates to easily create toolpaths after nesting objects in multiple sheets. This lesson applies to Vectric VCarve Pro, Aspire, and Cut2D Pro but some aspects can be used in the desktop versions . If you're nesting you don't need to array copy vectors. The nesting creates the extra copies for you. For the toolpaths the simplest way is to use layer association for each of . If your design consists of multiple parts that have to be cut from the same shee. This video covers how you can lay out a ready design on a sheet of material. The "Do Separate Last Pass" option in Vectric software is a toolpath setting that enables the CNC machine to cut material more precisely during a profile toolpath. It creates an .

How to use layers and toolpath templates to easily create toolpaths after nesting objects in multiple sheets. This lesson applies to Vectric VCarve Pro, Aspire, and Cut2D Pro but some aspects can be used in the desktop versions as well. If you're nesting you don't need to array copy vectors. The nesting creates the extra copies for you. For the toolpaths the simplest way is to use layer association for each of the toolpaths.

If your design consists of multiple parts that have to be cut from the same shee. This video covers how you can lay out a ready design on a sheet of material.

Nesting is used to group parts to use the least amount of material. To make it easy to associate toolpaths in the copies I create layers for each different toolpath type that I'm cutting. I put all the v-carved vectors on a layer, all the .25 endmills on a layer, etc.As step by step tutorial that shows the making of an embossed sign and creating the toolpaths to machine it on a hobby cnc router. I want to start from outside of my material and create a path into the first part and cut the entire outside profile and WITHOUT LEAVING THE SHEET continue onto the next part, essentially continuing in a chain around each successive part until I get to the last part. The "Do Separate Last Pass" option in Vectric software is a toolpath setting that enables the CNC machine to cut material more precisely during a profile toolpath. It creates an initial series of cuts slightly offset from the final line, followed by a dedicated last pass that cleans up the edge with precision.

CAD software generates the geometry of the part, while CAM software translates this geometry into a series of coordinates and actions that the CNC machine will execute, forming the actual toolpath. CAM software, such as Autodesk Fusion 360 or SolidCAM, enables machinists to design, simulate, and test these toolpaths before starting a physical . I have a part that has the inner cutouts done first then the outer cut which will free the part from the material blank. If I want to nest that toolpath to fill the material blank do I group that sequenced toolpath first then nest?Automated Toolpath Process Toolshops star feature, ATP, lets you import, toolpath, nest and export in a single click. Nesting Toolshop was designed about creating a faster & more accurate nesting algorithm. How to use layers and toolpath templates to easily create toolpaths after nesting objects in multiple sheets. This lesson applies to Vectric VCarve Pro, Aspire, and Cut2D Pro but some aspects can be used in the desktop versions as well.

If you're nesting you don't need to array copy vectors. The nesting creates the extra copies for you. For the toolpaths the simplest way is to use layer association for each of the toolpaths.

If your design consists of multiple parts that have to be cut from the same shee. This video covers how you can lay out a ready design on a sheet of material. Nesting is used to group parts to use the least amount of material. To make it easy to associate toolpaths in the copies I create layers for each different toolpath type that I'm cutting. I put all the v-carved vectors on a layer, all the .25 endmills on a layer, etc.As step by step tutorial that shows the making of an embossed sign and creating the toolpaths to machine it on a hobby cnc router. I want to start from outside of my material and create a path into the first part and cut the entire outside profile and WITHOUT LEAVING THE SHEET continue onto the next part, essentially continuing in a chain around each successive part until I get to the last part.

The "Do Separate Last Pass" option in Vectric software is a toolpath setting that enables the CNC machine to cut material more precisely during a profile toolpath. It creates an initial series of cuts slightly offset from the final line, followed by a dedicated last pass that cleans up the edge with precision. CAD software generates the geometry of the part, while CAM software translates this geometry into a series of coordinates and actions that the CNC machine will execute, forming the actual toolpath. CAM software, such as Autodesk Fusion 360 or SolidCAM, enables machinists to design, simulate, and test these toolpaths before starting a physical . I have a part that has the inner cutouts done first then the outer cut which will free the part from the material blank. If I want to nest that toolpath to fill the material blank do I group that sequenced toolpath first then nest?

bristol mailbox mounting bracket

nesting tool paths freecad

nesting tool path template

Shop Whirlpool 30 inches Convertible Under cabinet Range Hood Stainless Steel at Best Buy. Find low everyday prices and buy online for delivery or in-store pick-up. Price Match Guarantee. . Whirlpool 30" Convertible Range Hood. Manuals & Guides. User Manual. English; Measurement Guide. English; Installation Guide.

cnc how to nest part with toolpath|how to make toolpaths