14 gauge vs 16 gauge sheet metal Let us compare 16 steel gauge thickness to 14 steel gauge thickness. Looking at the numbers associated with their measurements and description, they are only ‘2’ apart from . See more Ford boxed the F150 frame beginning in 2004 (except the Heritage), 2004 and later Nissan Titans have a fully boxed frame. 2007 and later Tundra's have a boxed frame back to .

0 · steel ga thickness chart

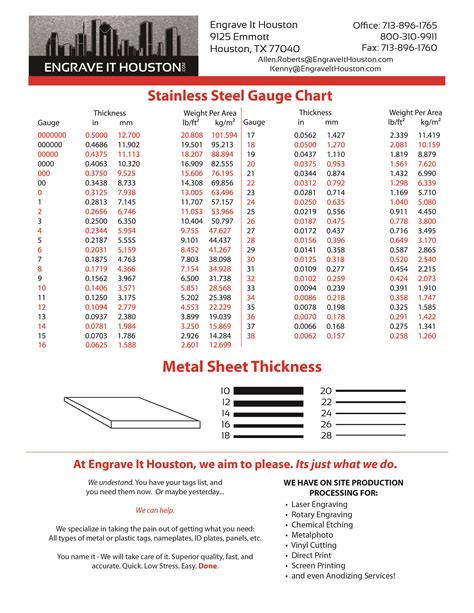

1 · stainless steel gauge thickness chart

2 · stainless steel gauge chart

3 · is 16 gauge steel strong

4 · is 14 gauge steel strong

5 · 16 gauge steel thickness

6 · 16 gauge steel strength

7 · 14 gauge steel strength

Simply put, “metal fabrication” is defined as creating products or structures by cutting, bending, and/or assembling metal material. It’s largely considered a value-added process as it consists of putting together actual products or structures from metal raw material.

As an amateur renovator, it can be kind of intimidating to walk into a store with the intention to purchase the supplies you need to complete the project at hand. Unfortunately, asking for help from a store associate is not always as helpful as you might originally hope for. Despite how kind and knowledgeable . See moreLet us compare 16 steel gauge thickness to 14 steel gauge thickness. Looking at the numbers associated with their measurements and description, they are only ‘2’ apart from . See more

Obviously, one of the biggest benefits of choosing thicker steel is the strength that comes with it. The project you are completing with the metal at hand will be much stronger if you . See more

The measuring unit and technique we used today can be dated back to the 19th century. British men working in the iron wire industry were the first to think of this universal measuring unit. The word “gauge” comes from the French word “jauge,” which . See moreUsing thicker and stronger metal means there will also be more work required of you. When the metal is strong, it’s harder to bend and shape to your needs. Attempting to use thick metal without the proper tools would be extremely difficult if not impossible. . See more

When working with sheet metal, the term “gauge” is often used. Gauge are used to . The chart below can be used to determine the equivalent sheet thickness, in inches .

steel ga thickness chart

For example, while 18-gauge steel might be suitable for a particular application due to its specific thickness and properties, 14-gauge steel could be more appropriate for projects requiring a thicker, more robust material. It's also .

In 14 vs 16 gauge steel, the 14 gauge steel sheet will be thicker than the 16 gauge steel sheet. As we go downward in the metal gauge chart, the gauge number increases and the thickness decreases. To be more precise, the 14 gauge . Which is thicker 14 or 16-gauge metal? 14 gauge metal is thicker. This ties back to the wire making origins of the gauge measurement system, as the number corresponds to the number of times the wire size was reduced, so .

In sheet metal fabrication, gauge thickness inversely correlates with the gauge number; as the gauge number increases, the material thickness decreases. For instance, 14-gauge steel is thicker than 20-gauge steel.

The difference in metric or standard value from one gauge to the next is not equal. For example, 18-gauge sheet metal made from aluminum is 0.040 inches, 20-gauge sheet .

stainless steel gauge thickness chart

A 14-gauge stainless steel sheet has a decimal equivalent of .0751. A 14-gauge carbon sheet has a decimal equivalent of 0.747. This means that in order to ensure your .

A 16 gauge thickness measurement is equivalent to .0625 inches of thickness. In comparison, a 14 gauge thickness measurement is equivalent to about .0781 inches of thickness. This means that the metal with the lower gauge number .When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system.

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter. For example, while 18-gauge steel might be suitable for a particular application due to its specific thickness and properties, 14-gauge steel could be more appropriate for projects requiring a thicker, more robust material. It's also worth noting the .

In 14 vs 16 gauge steel, the 14 gauge steel sheet will be thicker than the 16 gauge steel sheet. As we go downward in the metal gauge chart, the gauge number increases and the thickness decreases. To be more precise, the 14 gauge steel has a thickness of 0.0747 inches. Which is thicker 14 or 16-gauge metal? 14 gauge metal is thicker. This ties back to the wire making origins of the gauge measurement system, as the number corresponds to the number of times the wire size was reduced, so reducing the wire size 16 times results in a smaller diameter than 14 times.

In sheet metal fabrication, gauge thickness inversely correlates with the gauge number; as the gauge number increases, the material thickness decreases. For instance, 14-gauge steel is thicker than 20-gauge steel. The difference in metric or standard value from one gauge to the next is not equal. For example, 18-gauge sheet metal made from aluminum is 0.040 inches, 20-gauge sheet metal made from aluminum is 0.032 inches, and 16-gauge . A 14-gauge stainless steel sheet has a decimal equivalent of .0751. A 14-gauge carbon sheet has a decimal equivalent of 0.747. This means that in order to ensure your material meets the correct dimensional requirements for your . The decimal value of a 14-gauge copper sheet metal is equivalent to 2.108 millimeters or 0.0830 inches; Moving lower to a 12-gauge copper sheet metal is equal to 2.764 millimeters or 0.109 inches; Moving up to a 16-gauge copper sheet metal is equivalent to 1.651 millimeters or 0.065 inches

stainless steel gauge chart

A 16 gauge thickness measurement is equivalent to .0625 inches of thickness. In comparison, a 14 gauge thickness measurement is equivalent to about .0781 inches of thickness. This means that the metal with the lower gauge number .When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system.

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter. For example, while 18-gauge steel might be suitable for a particular application due to its specific thickness and properties, 14-gauge steel could be more appropriate for projects requiring a thicker, more robust material. It's also worth noting the .In 14 vs 16 gauge steel, the 14 gauge steel sheet will be thicker than the 16 gauge steel sheet. As we go downward in the metal gauge chart, the gauge number increases and the thickness decreases. To be more precise, the 14 gauge steel has a thickness of 0.0747 inches. Which is thicker 14 or 16-gauge metal? 14 gauge metal is thicker. This ties back to the wire making origins of the gauge measurement system, as the number corresponds to the number of times the wire size was reduced, so reducing the wire size 16 times results in a smaller diameter than 14 times.

In sheet metal fabrication, gauge thickness inversely correlates with the gauge number; as the gauge number increases, the material thickness decreases. For instance, 14-gauge steel is thicker than 20-gauge steel. The difference in metric or standard value from one gauge to the next is not equal. For example, 18-gauge sheet metal made from aluminum is 0.040 inches, 20-gauge sheet metal made from aluminum is 0.032 inches, and 16-gauge . A 14-gauge stainless steel sheet has a decimal equivalent of .0751. A 14-gauge carbon sheet has a decimal equivalent of 0.747. This means that in order to ensure your material meets the correct dimensional requirements for your .

can a cnc machine cut glass

can a ceiling fan be installed without a junction box

$27.99

14 gauge vs 16 gauge sheet metal|14 gauge steel strength