cnc milling aluminum part Capabilities of CNC Milling Aluminum Parts 6061-T6. Raw material – Al6061-T6 aluminum alloy plate Equipment – 3-axis CNC machine Cutting tools – Milling cutters, drills, taps, precision reamers, etc. Machining process – Blanking on . $105.99

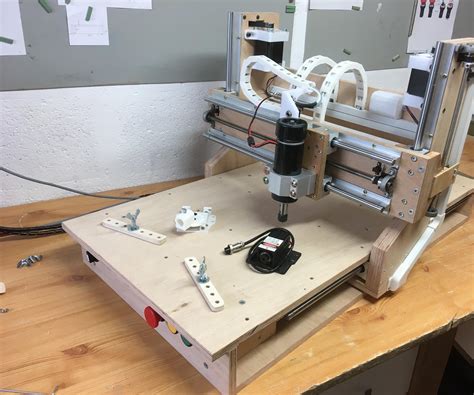

0 · hobby cnc milling machine

1 · hobby cnc mill aluminum

2 · hobby cnc machine for aluminum

3 · desktop cnc machine for aluminum

4 · desktop cnc aluminum milling machines

5 · best desktop cnc for aluminum

6 · best cnc router for aluminum

7 · best cnc machines for aluminum

Based in Adelaide, Williams Metal Fabrications offers design, steel fabrication, installation, contract labour, boat and crane truck hire. Learn more.

Lightweight, robust, and relatively inexpensive, almost every industry uses CNC-machined aluminum parts and other aluminum products. Learn all about the benefits, the most popular alloys, the best finishes, and more to ensure your .CNC milling machines are the most common and versatile way of machining aluminum parts. The machine uses rotating cutting tools to efficiently and .

The anodization method, which took place after the CNC machining is done, includes the flow of electric current through the CNC aluminum part in an electrolytic acid bath and results in a piece of Aluminum that is more corrosion .Capabilities of CNC Milling Aluminum Parts 6061-T6. Raw material – Al6061-T6 aluminum alloy plate Equipment – 3-axis CNC machine Cutting tools – Milling cutters, drills, taps, precision reamers, etc. Machining process – Blanking on .It is versatile and used for production in CNC machining, aluminum extrusion, and sheet metal fabrication processes. 6061 is the most popular grade aluminum material for CNC machining. Aluminum 6063 is good to be extruded, and aluminum 5052 is excellent for sheet metal forming. Aluminum has widespread uses due to its low bulk cost, natural .Various CNC machines, including milling, turning, and drilling machines, are employed to produce high-quality aluminum parts. Various machining processes, such as CNC machining, drilling, turning, and milling, are employed to produce high-quality aluminum parts, underscoring the broad applicability and efficiency of these techniques in the .

What is CNC Machining?CNC stands for computer numerical control. So, CNC machining is any kind of machining process controlled by a computer. Computerized au.

Aluminum is a non-ferrous metal commonly used in different applications. Manufacturers often utilize aluminum for various products because it is inexpensive, non-toxic, recyclable, and machinable, making it ideal for CNC machining.However, it is crucial to understand aluminum CNC machining to exploit its full potential of aluminum.High Speed CNC Milling Aluminum Alloy Plating Parts & Machine Sheet Parts. Unlock the full potential of your projects with our custom-tailored solutions – our high-speed CNC machined plating parts are the epitome of precision and quality. Crafted with meticulous attention to detail, our aluminum plating CNC-machined sheets are designed to .

Aluminum CNC Milling, the manufacturing process of using Computer Numerical Control, speeds up the production of many materials for a variety of industries. This procedure is suitable for a wide range of materials, particularly aluminum, but also other metals, plastics, wood, glass, foam and composites. Aluminum CNC Milling finds application in several industries, such as

Aluminum is a popular choice for machining due to its low density, good mechanical properties, high thermal and electrical conductivity, and resistance to corrosion. Aluminum alloys, such as 6061-T651, 7075-T651, and 2024-T351, are commonly used in CNC machining because they offer a good balance of strength, machinability, and cost.

Benefits of Custom Machined Aluminum Threaded Parts. Besides its exceptional machinability and corrosion resistance, aluminum delivers many benefits ideal for various CNC machining applications, from Swiss screw machining to CNC turning and milling to multi-spindle secondary operations. At DW Products, we offer a comprehensive range of equipment that manufactures .Aluminum is a material mainly used for CNC machining, for various features lightweight, soft, easy to handle, maneuverable, and durable.It is also non-ferrous and non-flammable. Since the material density is about 2.68, it is in the best position when it reaches this standard, and its melting point is about 640 degrees, which can be controlled.

How to Reduce Burrs when CNC Machining Aluminum Parts? Metal polishing is a surface finishing process that involves the removal of imperfections, scratches, and roughness from metal surfaces to achieve a smooth, reflective, and aesthetically pleasing appearance. This technique enhances the surface quality of metals while also improving their .When making aluminum parts, 3ERP offers several ways to combine 3-axis, 4-axis, or 5-axis CNC machining with other manufacturing processes in order to create more complex parts that can be made in large quantities. These process combinations can maximize the functionality of aluminum while still enjoying the benefits of other production processes.

CNC Machining is an established digital manufacturing process that produces high-accuracy parts with excellent physical properties directly from a CAD file. Although it’s been around since the early 50’s, recent technological advancements in digital supply chains have reduced the cost of CNC machining drastically and made it easily available to more professionals. Ive got some TiALN coated carbide ball endmills I would like to use for some 6061 parts for a rush job. Rush as in they want them tomorrow so it will run all night. I understand TiALN created an aluminum oxide coating when used, and is not recommended for machining aluminum. How bad is it for.

Aluminum extrusion, aluminum forging, CNC aluminum milling, CNC aluminum turning, CNC aluminum drilling, reaming and tapping. Davantech is recognized by its customers around the globe as a thrustworthy supplier and of custom made .CNC machining outsourcing is a manufacturing strategy that involves contracting with another company for CNC machining services. Whether for prototyping or production, product designers who outsource their machined parts gain . Burr formation is a common issue when milling aluminum parts using CNC machining centers. Burrs are undesirable projections leftover from the cutting process that must be removed through deburring operations. Minimizing burr formation when initially machining aluminum parts is beneficial for improving quality and reducing secondary processing.

Inventables have an older video of an X-Carve model CNC milling aluminum to make an LED ring for a spindle here: 3. Carbide 3D Shapeoko 4 XXL – Great for Small Businesses . If you really want to cut and mill aluminum and tougher parts seriously, consider stepping up into the CNC benchtop metal mill game rather than a CNC router. 7. Laguna .

Here we found six types of ways to minimize the aluminum part deformation in CNC machining. 1. Reduce the internal stress of the blank. Natural or artificial aging and vibration treatment can partially eliminate the internal stress of the blank.CNC mills or CNC milling machines produce parts of nearly any shape from soft metals like aluminum, harder metals like steel, and plastics such as acetal. eMachineShop offers cost-effective milling service whether you need a single part, batch of .

High precision OEM CNC Milling Turning service CNC machined productsIf you have some parts with high tolerance , high surface finish requirements or strict q.Aluminum: Lightweight and resistant to corrosion, aluminum is perfect for aerospace components, automotive parts, and more. Stainless Steel: Known for its strength and resistance to rust, it’s ideal for medical devices, automotive components, and food-grade machinery. Brass: With its excellent machinability, brass is often used for decorative pieces, electrical components, and .

CNC aluminum machining parts are also fantastic electrical conductors, which makes them perfect for making electrical parts. Environmentally Friendly and High Recyclability. The metal aluminum is malleable and soft. It has an exterior look of silvery gray and is easily obtainable. Aluminum is one of the most common preferable choices for CNC .Research And Development CNC Machining Parts Manufacturer. MK CNC part machining Co.,ltd was found in 2002. we are a factory area of 30,000 Square meters and over 300 worker. with 25 years of professional manufacturer of metal, including precision machining parts and anodizing, focusing on R&D and OEM/ODM service.Get an instant custom parts quote on our CNC Milling Services. 3, 4 and 5-axis machining capabilities. We produce your parts as fast as two days. Read more here. . Aluminum is a lightweight and highly versatile material that is widely used in various industries. It offers a unique combination of properties including high strength-to-weight .

Each of these points will influence how aluminum behaves during the machining process, and recognizing them can lead to more successful outcomes. 5 Key Tips to Prevent Aluminum Parts Deformation in Aluminum Machining. To maintain the integrity and dimensions of aluminum parts during CNC milling or CNC turning, several key strategies should be .

hobby cnc milling machine

hobby cnc mill aluminum

A black metal roof can make your house hotter due to its ability to absorb more heat from the sun compared to lighter colors.

cnc milling aluminum part|hobby cnc milling machine