wiki cnc machine Now the CNC in the processing manufacturing field has been very extensive, not only the traditional milling and turning, other machines and equipment are also installed with the corresponding CNC, which makes the manufacturing . See more

Junction boxes are used to collect and manage stormwater runoff from impervious surfaces like roadways and parking lots. Inlet pipes direct the stormwater to the junction box where it is temporarily stored before being safely discharged into the drainage system.

0 · who invented the cnc machine

1 · when were cnc machines invented

2 · computer numerically controlled machines

3 · cnc machines wikipedia

4 · cnc machine meaning in english

5 · cnc machine history

6 · cnc machine basic knowledge

7 · cnc machine acronym

Blanking: As previously highlighted, blanking involves removing a metal sheet and producing the desired shape. Shearing: The shearing consists of cutting straight lines in flat metal sheets. The primary goal is often to decrease the thickness of big sheets without altering their dimensions.

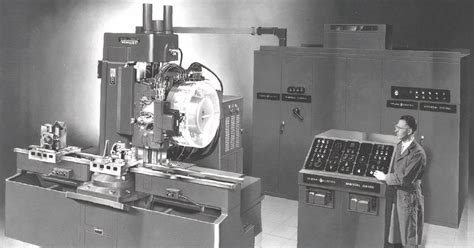

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) . See moreMotion is controlling multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate . See moreThe first CNC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the tool or part to follow points fed into the system on See more

what are the metal boxes on trucks called

Many other tools have CNC variants, including:• 3D printing• See moreWithin the numerical systems of CNC programming, the code generator can assume that the controlled mechanism is always perfectly . See moreNow the CNC in the processing manufacturing field has been very extensive, not only the traditional milling and turning, other machines and equipment are also installed with the corresponding CNC, which makes the manufacturing . See moreIn CNC, a "crash" occurs when the machine moves in such a way that is harmful to the machine, tools, or parts being machined, . See more

In numerical control systems, the position of the tool is defined by a set of instructions called the part program. Positioning control is handled using either an open-loop or a closed-loop system. In an open-loop system, communication takes place in one . See more

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can .The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the .CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or .

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the .The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .What is a CNC Machine? At its core, a CNC machine is a computer-controlled device that automates the operation of machine tools, such as mills, lathes, routers, and grinders. Unlike conventional manual machines, where operators .Numerical control processing (CNC) refers to the use of numerical control equipment for machining by mechanical workers.

This introductory article explains the main types of CNC machines, from CNC routers and milling machines, to less common types like Oxy-Fuel machines.

The CNC spark machine has many functions such as automatic profiling, automatic centering, automatic programming, G code programming, and three-axis linkage discharge. The Machine Characteristics Of EDM. Technical .Haas Automation, Inc is an American machine tool builder headquartered in Oxnard, California.The company designs and manufactures lower cost machine tools and specialized accessory tooling, mostly computer numerically controlled (CNC) equipment, such as vertical machining centers and horizontal machining centers, lathes/turning centers, and rotary tables .Uses: This CNC spinning machine is suitable for industries such as lamps, cookware, tableware, and handicrafts. Can complete barrel type, cone type, parabolic type, la; Batch production of horn type and warhead type products. Features: This CNC spinning machine is economical. Mainly for the products of copper, iron, aluminum, and stainless .

A CNC wood router uses CNC (computer numerical control) and is similar to a metal CNC mill with the following differences: . The wood router typically spins faster — with a range of 13,000 to 24,000 RPM; Professional quality machines frequently use surface facing tools up to 3" in diameter or more, and spindle power from 5 to 15 horsepower.

The high-power engraving machine can be used as a small-power engraving cnc machine. It is most suitable for large-scale cutting, embossing and carving. In the numerical control machine tool, the electric spindle usually adopts the frequency conversion speed regulation method. There are mainly three control modes: ordinary variable frequency .Machine tool monitoring is explained with Acoustic Emission (AE) sensors. [7] An AE sensor is commonly defined as the sound emitted as an elastic wave by a solid when it is deformed or struck, caused by the rapid release of localized stress energy.Therefore, it is an occurrence phenomenon which releases elastic energy into the material, which then propagates as an .

The CnC Machine is a block added by the Mad Science mod. A powerful device used in creating the components required for the M41A Pulse Rifle.It requires energy, water, and a Redstone signal to operate. In order to properly craft items with this machine, a binary code is written to a book and quill, signed and inserted into the top slot of the machine as instruction on how to cut .The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.. The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the .The CNC polishing machine servo constant pressure polishing, real-time compensation for consumables loss; the polishing disc is driven by an independent motor, and the positive and negative rotations are automatically switched to meet the needs of different processes; the CNC polishing machine is mainly used for mobile phones of non-metallic materials such as glass, .A 3-axis clone of a Bridgeport-style vertical milling machine. Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpiece.This may be done by varying directions [2] on one or several axes, cutter head speed, and pressure. [3] Milling covers a wide variety of different operations and machines, on scales from small individual .

Five-axis linkage CNC machine tool is a high-tech, high-precision machine tool specially used for processing complex curved surfaces. This machine tool system is useful for a country’s aviation, aerospace, military, scientific research, precision equipment, high-precision medical equipment, etc. The industry has a decisive influence.The CNC cutting machine has the characteristics of fast cutting speed and small slitting during the cutting process. The design of the industrial master machine tool ensures the high speed and stability of the laser cutting process. It is equipped with fiber lasers of different powers, which can cut and perforate various metals and materials at . 2021-10-24 Cnc Machining Guide Comments Off on The working principle of the static pressure screw in the CNC machine tool feed system. 1. Working principle The ball screw nut pair is a transmission pair that puts balls between the screw and the nut, and the screw and the nut become a driving pair of rolling friction. .Swiss Machine-the full name is the spindle-type CNC lathe, it can also be called the headstock mobile CNC automatic lathe, the economical turning-milling compound machine tool or the slitting lathe. It is a precision processing equipment that can complete lathe, milling, drilling, boring, tapping, engraving and other compound processing at one .

what color shutters on house with maroon metal roof

CNC machine tools are mainly used to process parts with complex shapes, but the structure of the fixtures used is often not complicated. The selection of fixtures for CNC milling machines can first be determined according to the batch size of the production parts. For single-piece, small-batch, and large-volume mold processing, positioning and .The CNC bending machine uses the equipped Mold (general or special Mold) to bend the cold metal sheet into various geometric cross-sectional shapes. It is a sheet forming machine designed for cold-rolled sheet metal processing, and is . Like all CNC machines, the SmartShop II is most useful when a design calls for a high level of precision, or is being mass produced. Here is an example of this piece of equipment being used. Documentation Terminology. .En CNC-laserskæremaskine. Forkortelsen CNC betyder Computer(ized) Numerical(ly) Control(led) (computeriseret numerisk styret), og refererer til produktionsmaskiner, der ved hjælp af en computer kan fremstille mange ensartede komplekse dele i metal og andet materiale, og som programmeres i et sprog, der overholder EIA-274-D-standarden (også kaldet ISO .

The Advantage Of Turn-Mill Machine. Compared with conventional Cnc Machining technology, the outstanding advantages of compound machining are mainly manifested in the following aspects.. Shorten the product manufacturing process chain and improve production efficiency.Wondering if this is the right machine for you? Check the performance page. TLDR: PrintNC relies on 3D printed parts to ensure accurate construction, but all motion components are mounted to steel or aluminium, resulting in a rigid and capable DIY CNC router. Understand that this is a rapidly-evolving project.

3D Cnc Machine, also known as 3D Printer (3DP for short) is a process of Rapid Prototyping (RP), which uses layer-by-layer stacking to create a three-dimensional model. Its operation process is similar to that of a traditional printer. It’s just that traditional printers print ink on paper to form a two-dimensional plan drawing, while three .Cnc Carving Machine can be used for cutting, two-dimensional engraving and three-dimensional engraving on various flat materials. In addition, the main functions and advantages of the multi-functional metal plaque engraving machine: powerful, multi-purpose, no matter whether it is making bronze, stainless steel, titanium, aluminum and other .According to its output power, it is divided into 900W plastic welding machine, 2600W plastic welding machine, 3200W plastic welding machine, 4200W plastic welding machine, 5600W plastic welding machine, etc. What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials.; Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.Each machine has its own advantages and .

ANCA Pty Ltd (formerly Australian Numerical Control and Automation Pty Ltd) is an Australian company which designs and manufactures computer numerical controlled grinding machines.The company was founded in 1974 by Pat Boland and Pat McCluskey in Melbourne, Australia.. ANCA has its headquarters and main manufacturing plant in Melbourne where it employs about 400 . Coordinate system and direction of motion 1. The principle of determining the coordinate system. 1) The principle of the tool moving relative to the stationary workpiece This principle stipulates that regardless of whether the CNC machine tool is a tool movement or a workpiece movement, the program is written based on the tool’s trajectory during .The CNC machining center is currently one of the most widely used CNC machine tools in the world. Its comprehensive processing ability is relatively strong. After the workpiece is clamped, it can complete more processing content. The processing accuracy is high. For batch workpieces with medium processing difficulty, its efficiency is 5 to 10 .

who invented the cnc machine

what are the metal pipes outside my house

when were cnc machines invented

computer numerically controlled machines

There are so many advantages for us to use machined parts. However, we should be aware that nothing is 100% definitely perfect in a way. When we enjoy all the benefits of custom machined parts mentioned above, please keep in mind the following limitations . See more

wiki cnc machine|cnc machine meaning in english