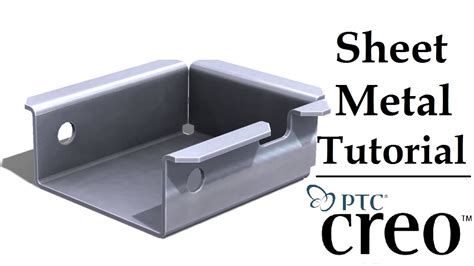

convert part to sheet metal creo 3.0 If you use my technique - transform solid model to surface and then you use offset feature, you can unbend any imported geometry and selct only necessary surfaces to unbend - create a Flat State.. Have you ever noticed a star adorning the exterior of a house and wondered about its significance? These stars are seldom the same, often seen in various colors, sizes, and materials — they are not just decorative elements; they carry a wealth of history and meaning.

0 · sheet metal in creo parametric

1 · creo sheet metal tutorial pdf

2 · creo sheet metal tutorial

3 · creo sheet metal basics

4 · creo parametric sheet metal tutorial

5 · creo 8 sheet metal

6 · converting to sheet metal parts

7 · convert solid part to sheet metal

I may have to delete this account but word from reliable sources is that all those with those specific golden stars actually have access to the secret bunker under Roanoke Memorial Hospital. The star on mill mountain is a beacon for .

Starting with Creo Parametric 5.0, when you convert a solid part to a sheet metal part you can include and exclude surfaces to obtain a constant wall thickness, recreate rounds and .Creo does not recognize the part when trying to convert it to sheet metal as .Use the Convert to Sheet Metal tool in Part mode to change a solid part into a sheet metal part. The solid part geometry is referenced to create the first wall. For a block-like part, use the . If you use my technique - transform solid model to surface and then you use offset feature, you can unbend any imported geometry and selct only necessary surfaces to unbend - create a Flat State..

Creo does not recognize the part when trying to convert it to sheet metal as picking Driving surface. One way to do it of course it is to convert it . Error messages: Cannot convert to Sheetmetal while in insert mode; Conversion to Sheet Metal Part in Insert Mode works in Creo Parametric 2.0, but not in 3.0; Reproduce: .

On completion of this course, the student will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts. Topics Covered: The . On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts. .Creo Parametric 3.0: Sheet Metal Design April 2016. April 2016. Read More. Corporate: Ascent - Center for Technical Knowledge; Publisher: ASCENT Center for Technical Knowledge; ISBN: .

Correct me if I'm wrong, but can't you model it as you have it here, then use the "convert to sheetmetal" functionality? Or make the bent piece without the straight bit, then add it as a feature?Starting with Creo Parametric 5.0, when you convert a solid part to a sheet metal part you can include and exclude surfaces to obtain a constant wall thickness, recreate rounds and chamfers, and use additional options.Use the Convert to Sheet Metal tool in Part mode to change a solid part into a sheet metal part. The solid part geometry is referenced to create the first wall. For a block-like part, use the Shell tool to remove one or more walls and to set the wall thickness. If you use my technique - transform solid model to surface and then you use offset feature, you can unbend any imported geometry and selct only necessary surfaces to unbend - create a Flat State..

Creo does not recognize the part when trying to convert it to sheet metal as picking Driving surface. One way to do it of course it is to convert it as a surface, copy surfaces, convert to sheet metal and use offset tool.

sheet metal in creo parametric

creo sheet metal tutorial pdf

Error messages: Cannot convert to Sheetmetal while in insert mode; Conversion to Sheet Metal Part in Insert Mode works in Creo Parametric 2.0, but not in 3.0; Reproduce: .On completion of this course, the student will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.

On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts. Topics Covered: The sheet metal environment

On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts. Topics Covered. The sheet metal environment; Primary and secondary walls; Bend relief; Corner relief; Regular unbends, back bends, and cuts; Notches and punches; Bend featuresCreo Parametric 3.0: Sheet Metal Design April 2016. April 2016. Read More. Corporate: Ascent - Center for Technical Knowledge; Publisher: ASCENT Center for Technical Knowledge; ISBN: 978-1-943184-61-3. Published: 14 April 2016. Pages: 426. Available at . Correct me if I'm wrong, but can't you model it as you have it here, then use the "convert to sheetmetal" functionality? Or make the bent piece without the straight bit, then add it as a feature?

Starting with Creo Parametric 5.0, when you convert a solid part to a sheet metal part you can include and exclude surfaces to obtain a constant wall thickness, recreate rounds and chamfers, and use additional options.Use the Convert to Sheet Metal tool in Part mode to change a solid part into a sheet metal part. The solid part geometry is referenced to create the first wall. For a block-like part, use the Shell tool to remove one or more walls and to set the wall thickness. If you use my technique - transform solid model to surface and then you use offset feature, you can unbend any imported geometry and selct only necessary surfaces to unbend - create a Flat State..

Creo does not recognize the part when trying to convert it to sheet metal as picking Driving surface. One way to do it of course it is to convert it as a surface, copy surfaces, convert to sheet metal and use offset tool. Error messages: Cannot convert to Sheetmetal while in insert mode; Conversion to Sheet Metal Part in Insert Mode works in Creo Parametric 2.0, but not in 3.0; Reproduce: .On completion of this course, the student will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.

On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts. Topics Covered: The sheet metal environment On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts. Topics Covered. The sheet metal environment; Primary and secondary walls; Bend relief; Corner relief; Regular unbends, back bends, and cuts; Notches and punches; Bend featuresCreo Parametric 3.0: Sheet Metal Design April 2016. April 2016. Read More. Corporate: Ascent - Center for Technical Knowledge; Publisher: ASCENT Center for Technical Knowledge; ISBN: 978-1-943184-61-3. Published: 14 April 2016. Pages: 426. Available at .

creo sheet metal tutorial

metal fabrication schools ontario

A septic tank’s distribution box (or D-box) is a container (typically concrete) that receives the septic tank effluent and re-distributes it into the network of attached drain fields and pipes. To put it simply, its job is to evenly distribute the wastewater into the leach field.A septic distribution box, also known as a D-box, is a crucial component of a septic system. Its primary function is to receive the effluent (wastewater) from the septic holding tank and evenly distribute it to the various distribution lines .

convert part to sheet metal creo 3.0|creo sheet metal tutorial